Often times, trailers (particularly home builds) are pieced together using a variety of parts. Some of these parts are used because they are readily available at the time and can be had for a good a price. Unfortunately, these parts can subsequently become a source of difficulty and confusion.

Mobile Home axles and brakes are uniquely designed and built to serve a very specific function. First and foremost, they only need to get a home from point A to B, presumably only ever being used once. Because of this narrow application, manufacturers build them with the understanding that these parts will not require repairs or need to be replaced during their intended service life.

While purpose built mobile home axles have some things in common with their trailer axle cousins they differ in a few critical ways. MH axles share the same tube diameters, brake size and weight capacity as their trailer equivalents. On the other hand, they often do not have brake flanges (backing plates are usually welded to the axle). They typically use oddball bearing configurations and lastly, they have a “Demountable” style bolt pattern.

So now that you know the basics, let’s jump into scrutinizing and identifying your parts.

The first thing I do when someone brings me a demountable drum is I check the bearings. We can identify them by reading the numbers stamped in them (if they are still visible) or measuring the Inside Diameter of them. If the bearings have been lost or damaged beyond recognition, we move on to identifying the races in the drum. They will also be stamped with an identifying number. If neither is available, we will have to measure the spindle of the trailer. A good article detailing this process can be found here.

Typically, there are only two bearing configurations you will see on these types of drums, 1-3/8” x 1-1/4” or 1-1/4” x 1-3/4”. Either way, it will be critical to identify the inside diameter of the grease seal and ensure that selected drum matches in every way.

| Bearing Number |

Bearing Size |

Race Number |

| L68149 |

1.38 |

L68111 |

| L67048 |

1.25 |

67010 |

| 15123 |

1.25 |

15245 |

| 25580 |

1.75 |

25520 |

Brake Backing Plates

Typically, demountable drums will use a brake size of 12”x2”. If this is the case for you, in most instances the brake’s “backing plate” is welded to the axle. All this means is that you will have to spend the time rebuilding the assembly. Reassembling a drum brake is a somewhat tedious process but with time and commitment it can be done. Typically, the most cost effective way to purchase these parts is to buy an entire pre-assembled backing plate, strip it down and resemble on your axle. This also offers the benefit of you being able to see how the assembly should look in the end; this is especially helpful if you are unfamiliar with drum brakes. Drum brakes are very “old school” and some of us (especially us younger guys) may not have dealt with them until now. There will be a little trial and error. There are tons of excellent sources to be found on the internet detailing every step in the process of reassembly.

For those looking to switch to a standard 6 or 8 lug pattern.

Quite often, people who have demountable drums have a desire to change over to a more standard 6 on 5.5” or 8 on 6.5” bolt pattern. This will only be possible if you have a 1-1/4” x 1-3/4” bearing configuration. If you have the 1-3/8” x 1-1/4” bearings, you will have to change your axles which will be a more costly process than just retaining your old setup.

Eastern Marine has available a large selection of RV storage covers. We have a range of covers available for a variety of RV’S, including class A, B and C. As well as 5th wheel, toy hauler and popup or truck camper covers. We also stock a large selection of RV accessory covers.

We stock a selection of three different Classic Accessories covers. They are categorized by three names, the Poly Pro 1, Poly Pro 3 and the Perma Pro. They are all similar but offer a number of additional benefits as you move up the line.

Poly Pro 1:

The Poly Pro 1 is Classic Accessories entry Level RV Storage cover. It is a 1-ply non-woven Polypropylene Fabric. Polypropylene is a versatile thermoplastic material. It is low density, chemical and thermal resistance and is excellent for use as a moisture and oxygen barrier that also happens to be fully recyclable. It is well suited for use as a weather resistant cover. The Poly Pro 1 is backed by a 1 year manufacturer’s warranty from the date of purchase.

Poly Pro 3:

The poly Pro 3 is similar to the 1 but more durable. It uses the same reliable polypropylene fabric however; it has a 1-ply non-woven sides and 3-ply non-woven tops. This ensures better durability to the cover and this is reflected by a manufacturer’s 3 year warranty beginning at the date of purchase.

Perma Pro:

The Perma Pro uses a 100% woven polyester rip stop fabric. Polyester is a durable synthetic fiber that is flexible and resistant to wrinkles and shrinkage. During the weaving of the tarp, thick, reinforcing threads are interwoven at regular intervals in a crosshatch pattern. This provides excellent resistance to tearing and abrasion. The Perma Pro carries a limited lifetime warranty through Classic Accessories.

Vents are an important part of any recreational vehicle. They are designed to keep fresh air circulating throughout your motor home, release cooking fumes and other odors and reduce humidity created by your shower. Because of their location, vents take a beating. They are exposed to constant direct sunlight as well as bearing the brunt of any inclement weather. All of this means that they will wear out and eventually require replacement.

Replacing your RV Vent and related components is quite simple. One of the most common questions we are asked here at Eastern Marine is “which vent do I need for my RV?” Finding the answer to this question requires simple measurements and in some cases, visual identification.

Vent Replacement

First and foremost, we have to remove the old vent to measure the “rough opening”. Most of the time, your standard rough opening should measure somewhere in the ballpark of 14.25” x 14.25”. There will however always be exceptions to the rule and we have to measure first to be sure. Once we’ve found our rough opening, we have to decide what other features we desire in our vents. For example, some vents have an electrically powered fan that assists in increasing air flow. Other vents have semi translucent or galvanized steel cover. When replacing the whole vent, you should also replace all of the seals and screws which can be purchased as a kit. We also offer replacement garnish rings in varying depths. Once you have identified this information, one can be chosen from the list of vents.

Cover Replacement

When replacing the cover only, we have to look at two equally important parts of the cover, the dimensions and the hinge style. The same general dimension rule applies to covers only, most will be 14″ x 14″ but we must still measure to be certain. After we have determined the dimensions of our cover, we have to identify the hinge style. The easiest way to do this is to use the reference photos below provided by Camco. All of our replacement covers can be found here.

Accessories

Sometimes all you need is that replacement knob or a new fan blade for your vent. In addition to vent assemblies and covers, we offer a number of accessories and replacement parts. We have everything from replacement 12v fan motors to insulation panels that can all be found here.

Eastern Marine Carries three excellent Electric A Frame Trailer Jacks. We offer two from Lippert Components Industries and one from Buyers Products.

Lippert Components Industries (LCI) produces two outstanding jacks. The first is their standard model. It operates using a traditional toggle switch that is illuminated by LED lights. It also includes all mounting hardware needed to bolt into your RV’s A frame jack slot. It comes with a backup manual hand crank in case of an emergency and is capable of lifting 3500lbs.

If your seeking something with a few more bells and whistles, LCI also offers a line of jacks called the “Smart Jack”. The smart Jack has an internally illuminated control panel for use in low light conditions. The control panel also features a battery indicator that alerts users to the remaining battery life. The Smart Jack also has LED lights that illuminate the tow vehicle’s ball and RV coupler. It also includes all mounting hardware as well as an emergency hand crank.

Both LCI jacks offer 18″ of stroke and draw a meager 30 amps of power. They are charged via your tow vehicle’s 7 Blade RV plug.

Buyers Components offers a no nonsense entry level Electric Jack. Their model is basic but functional. We have carried this Jack for over 6 years now and it is a work horse. It offers an industry standard lift capacity of 3500lbs. It comes pre wired with a 48″ 7 Blade RV plug. The Buyers jack has 18″ of powered lift and can gain an additional 6″ with the use of the included adjustable foot pad.

In addition to jacks, we also offer a plethora of accessories to assist in proper leveling of your RV or Motor Home. Everything from bubble levels to outrigger pads that can be found at this link.

In an effort to continually offer new and useful Recreational Vehicle products to our customers, we would like to highlight the availability of Lippert RV & Camper Entry Steps. Our selection consists exclusively of the “Kwikee” and “Tread Lite” step series. They each offer their own unique features and are both designed to meet a variety of consumer demands.

Kwikee Steps

Lippert’s Kwikee steps are electrically powered and are actuated via a sturdy 12v DC motor with fully sealed electrical connections. The DC motor drives a solid steel rod that is encased in a durable stainless steel sleeve. To increase the quality and durability of their steps, Lippert constructs every Kwikee using air pressed rivets at all pivot points. With occasional greasing to the rivets you can ensure years of continuous use. Each Kwikee assembly features steps with built in grip surfaces that are garnished with high visibility reflective yellow strips. Kwikee steps are capable of supporting up to 750 pounds and are available in single, double and triple step assemblies. They are mounted by bolting directly to the frame of your RV or Travel Trailer via pre-drilled bolt holes.

Tread Lite

Tread Lite steps are Lippert’s top of the line Assembly. They are functional, lightweight, aesthetically pleasing and fully automated. The Tread Lite steps are actuated via a sturdy 12v DC motor and offer a number of additional features over the Kwikee series. Tread Lites have integrated LED lighting to provide better visibility as well as anti slip coated surfaces to ensure solid footing. They can also be synced to auto extend and retract with your RV’s door. As an added safety feature, the steps are able to detect obstructions in their path. The steps can also be extended indefinitely while camping by using the “hold cycle” switch. They are constructed with anodized aluminum and on average run 13lbs lighter than the average competitors equivalent assembly. They are also available in single, double and triple step assemblies and are capable of supporting up to 350 pounds. Tread Lite steps will have to be bolted directly the frame of your RV or travel Trailer using pre-drilled holes.

Posted Under:

RV / Camper Parts

This post was written by

ghoj on October 18, 2017

Comments Off on RV Folding Steps

Since 1981, Eastern Marine has served America with our unique blend of Discount Boating, Fishing, RV and Trailer Parts & Equipment. For 36 years our core specialization and distribution of Trailer Parts has continued to grow in size and scope.

We now offer a huge selection of cross-application RV & CAMPER PARTS such as: tail lights, tires, wheels, axles, leaf springs, frame hardware, tongue jacks, couplers, safety chains, towing equipment, brakes and much more from top name brand manufacturers.

In addition to our huge selection of under-carriage equipment, our selection of Recreational Vehicle specific accessories continues to grow each year. Now you have one-stop-shopping access to trailer hardware plus RV accessories including:

* RV Fresh Water Systems

* RV Water Heaters

* RV Sanitation, Toilets, Hoses & Holding Tanks

* RV Entry Steps

* RV Stoves and Furnaces

* RV Stabilizer Jacks & Tongue Jacks

* RV Electrical & Lighting

* RV Window, Door & Hatch Parts

* RV Slide-Out Parts

* RV Vents, Fans & Skylights

* RV Refrigerators

* RV Ladders, Awnings & Ground Gear

* RV Housewares, Kitchen & Bath

So stop on by our Newark, DE showroom or browse online for all your RV / Camper & Trailer Parts equipment at the official TRAILER PARTS SUPERSTORE®!!!

Posted Under:

RV / Camper Parts

This post was written by

ghoj on September 26, 2017

Comments Off on RV / Camper Parts & Accessories

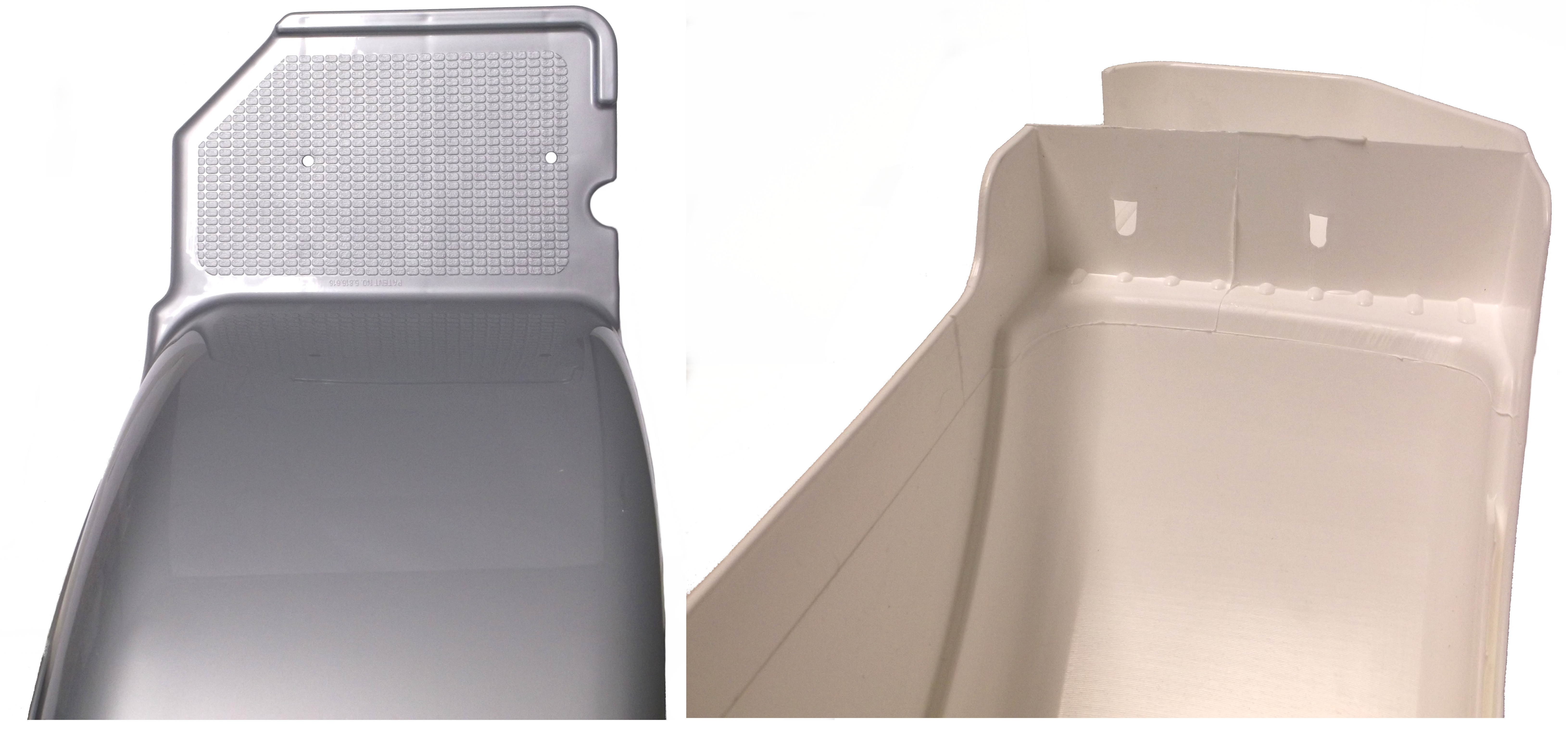

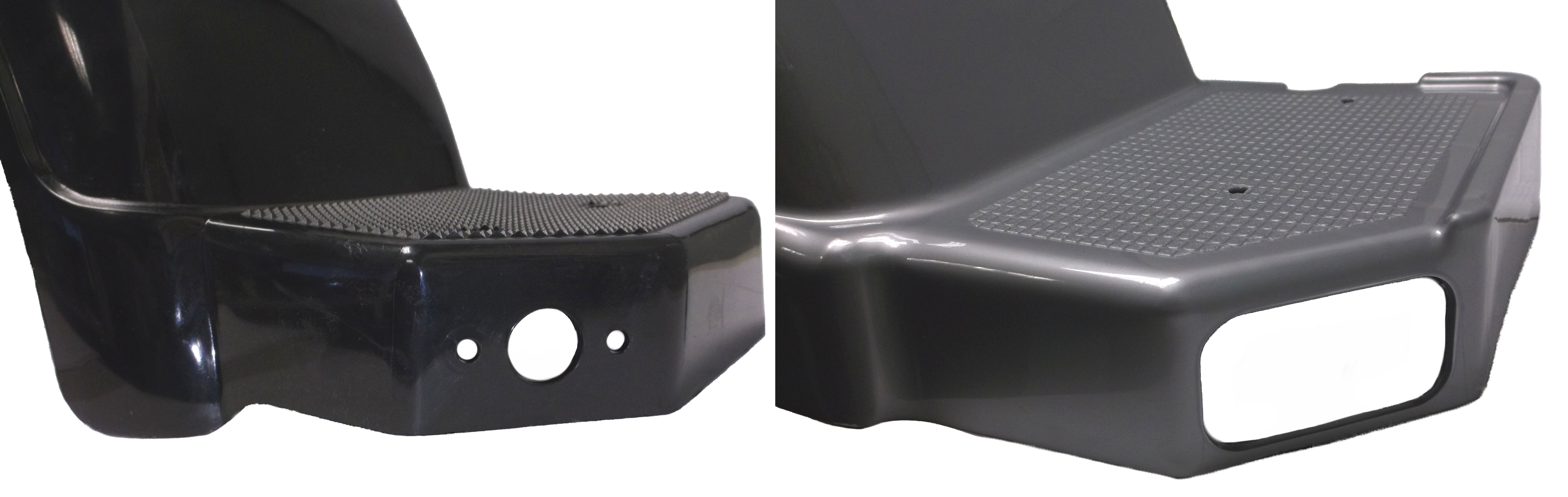

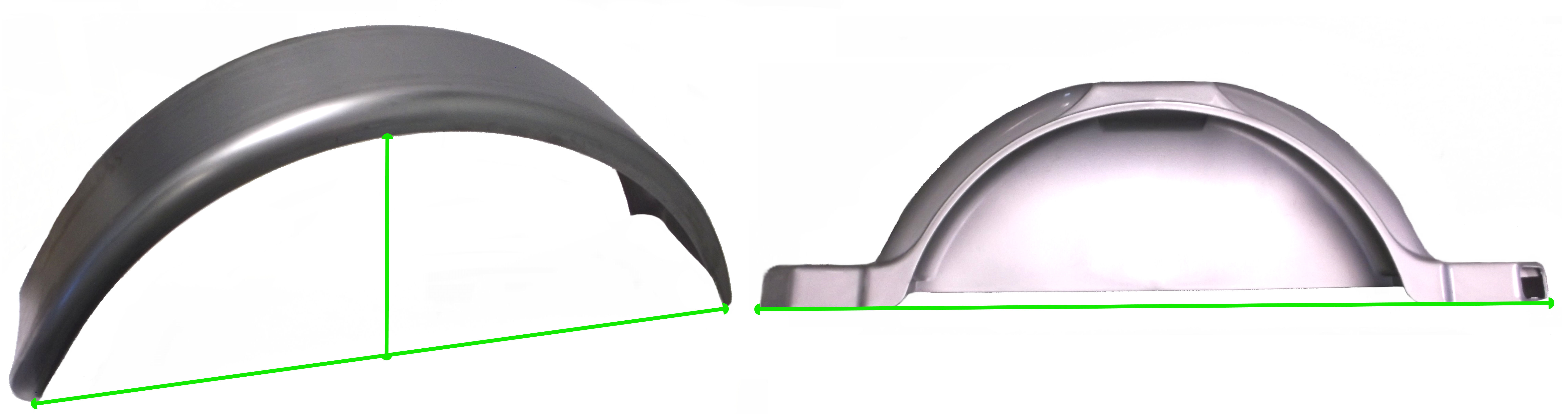

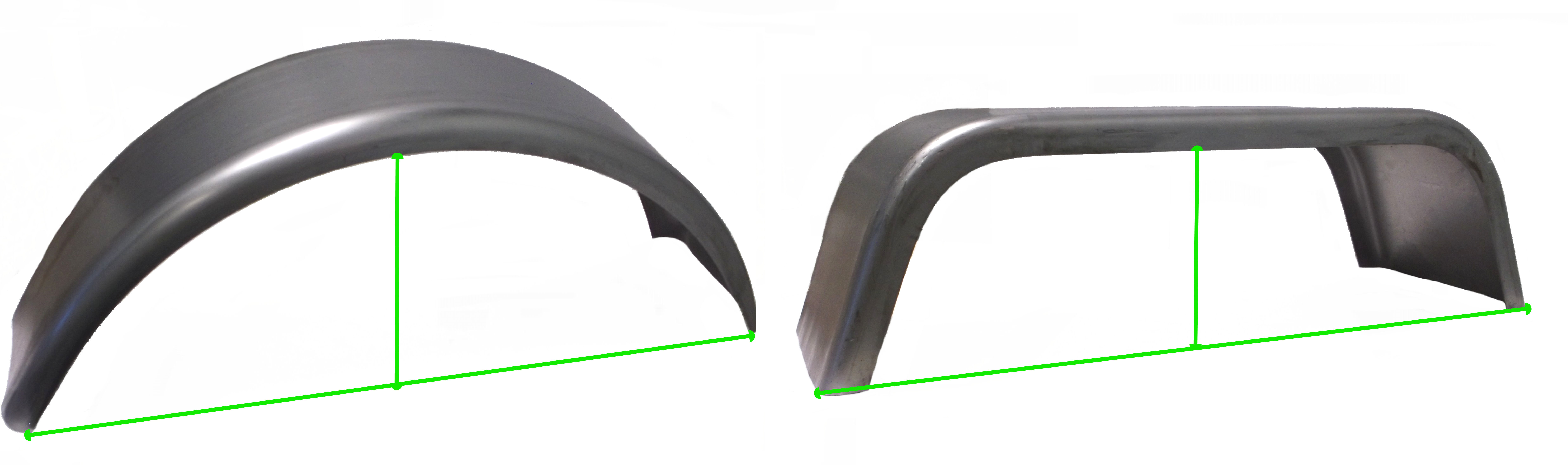

Trailer Fenders

Fenders, while seemingly innocuous, are actually an essential part of your trailer. Fenders protect your boat and trailer as well as other vehicles on the road from debris. Fenders can also provide a stepping point for accessing both your boat and trailer. For these reasons and many more, it is important to maintain and care for your fenders and when the time comes, find a suitable replacement.

That being said, you may be wondering where to begin. The process we use to determine which replacement fender you need is based in large part around narrowing the search. As you will see below, this is done using basic observations and a few simple measurements.

Observations about your trailer

- Who manufactured your trailer?

- If possible, identify who manufactured the trailer. This is a useful piece of information and can really help narrow your search. Your trailer’s registration or title are both good resources if the trailer’s markings are no longer there. If it is not possible to identify the brand you can still find your replacement fender without it.

- What is your tire size?

- While tire size can slim down the options, this is not the only factor used to determine your fenders size. Just because a fender has a description that calls for use on “x” sized tire, it does not mean that it cannot be used with other sized tires.

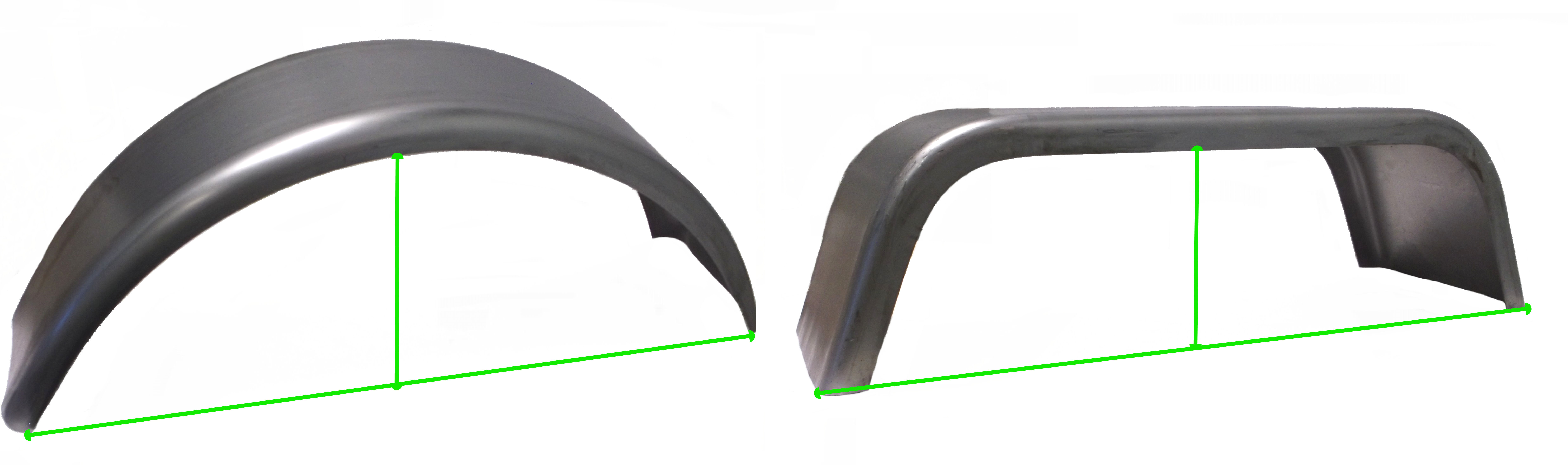

- How many axles are on your trailer?

- The number of axles on your trailer will help determine what fender you need and assist in narrowing the search.

Observations about the fender

- What material is the fender made out of?

- Generally speaking, most fenders are made out of one of three materials, plastic (available in black, white and grey) steel (galvanized or raw) and aluminum (diamond plate or smooth)

- How does your fender bolt to it’s mounting bracket?

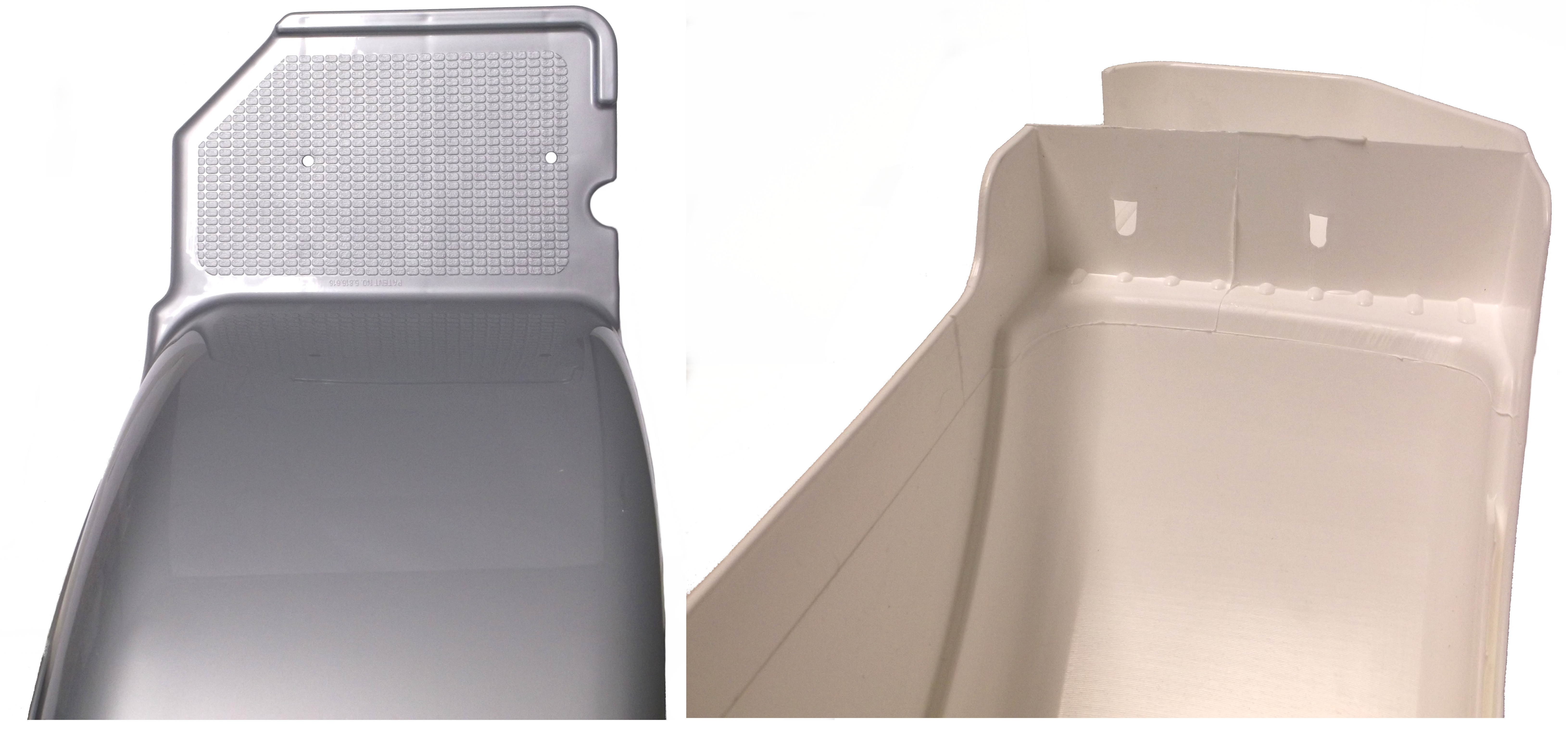

- Plastic fenders typically bolt to the mounting bracket in one of two ways. Karavan style “Top Mount” or Standard style “Side Mount” (As shown in photos below).

- If the fender is steel, take note of whether it is welded or bolted to the trailer.

Left: “Top Mount” Holes Right: “Side Mount” Holes

- Does the fender have lights?

- If the fenders have cut outs for marker lights, you will have to make a few observations.

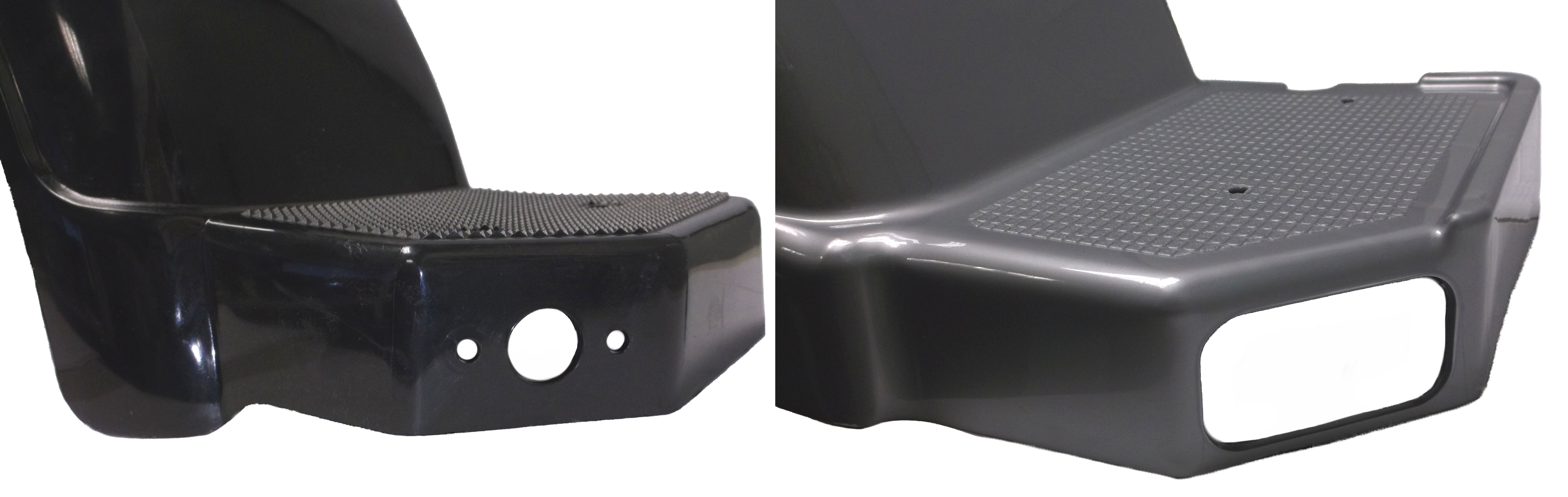

- How is the light fixed to the fender? Rectangular/round rubber grommet, etc (See photo below)

- What color is the light?

- Is the light LED or incandescent?

- If it does have lights, you will have to know if the fender is on your left side (Driver’s/Road side) or Right side (Passenger’s/Curb Side)

Left: Circular Style Right: Rectangular Style

- What style is the fender?

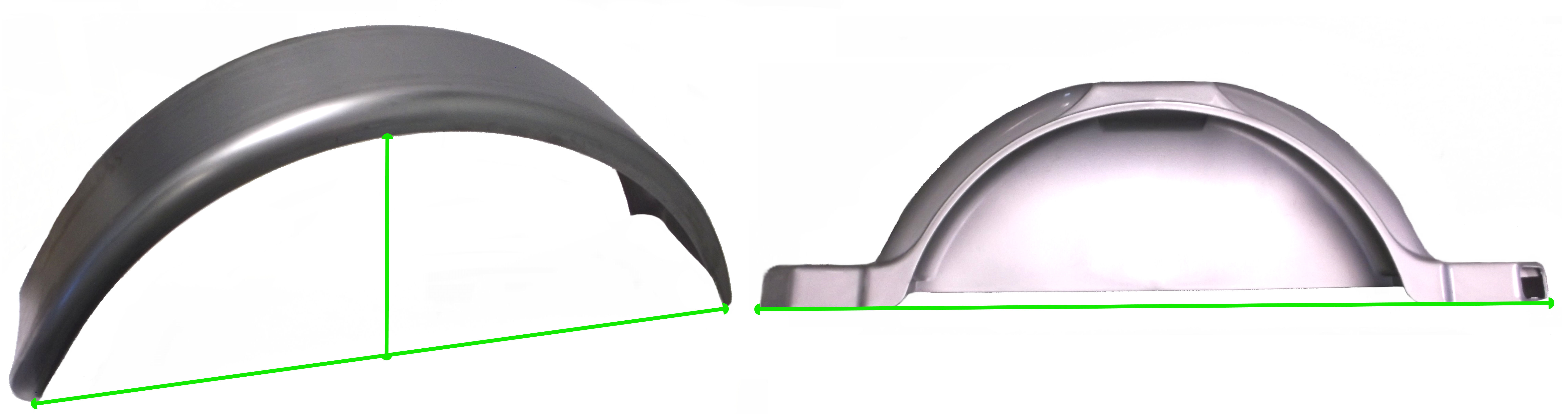

- Does the fender have rounded ends or “Jeep Style” square ends?

Left: Standard Oval Radius Right: Jeep Style

Measuring the fender

- Overall length: Trailer fender overall length is measured by going from the farthest point of the fender to its parallel opposite.

- Inside length: Fender inside length is typically taken when attempting to replace plastic fenders that have 1 or more steps incorporated into its design. It is measured between the inside mounting flanges of the fender (where it will bolt to the mounting bracket)

- Width: Width is very simple, just measure from the back face to the front face of the fender at its widest.

- Height: The easiest way to measure height is with the fender removed from the trailer. Simply place the fender on a flat surface and measure from the ground up.

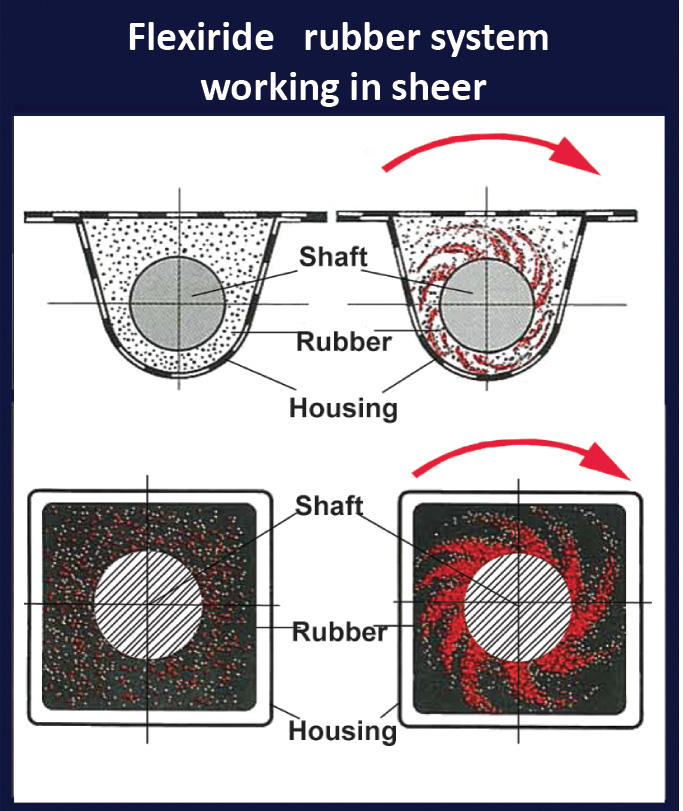

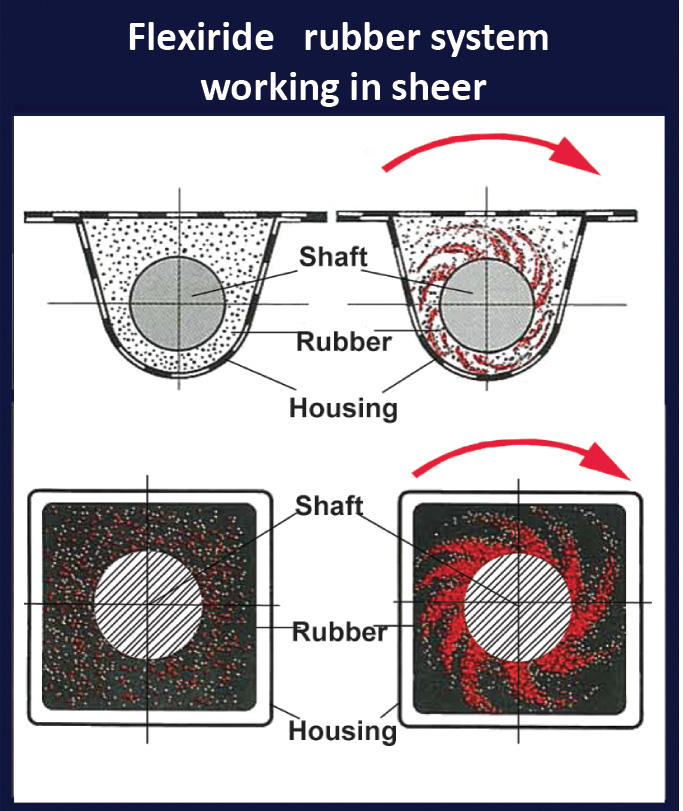

Our new Flexiride axles from the Universal Group provide one of the smoothest rides available for your trailer. Traditionally, trailer axles relied on the compression of leaf springs to allocate suspension support. Flexiride Torsion axles provide this needed support in a different way. Using a hydraulic press, hardened steel shafts are pressed into into a solid rubber cartridge within the half axle tube. Torsion axles use the shear resistance of this steel rod within the stiff rubber cartridge to provide shock absorption. Torsion axles are able to provide better vibration dampening and shock absorption than their conventional leaf spring counterparts.

Flexiride axles are offered in a variety of weight capacities ranging 425 lbs to 7000lbs and in a variety of hub configurations. Several are available with bare spindles, idler hubs and electric or hydraulic drum brakes.

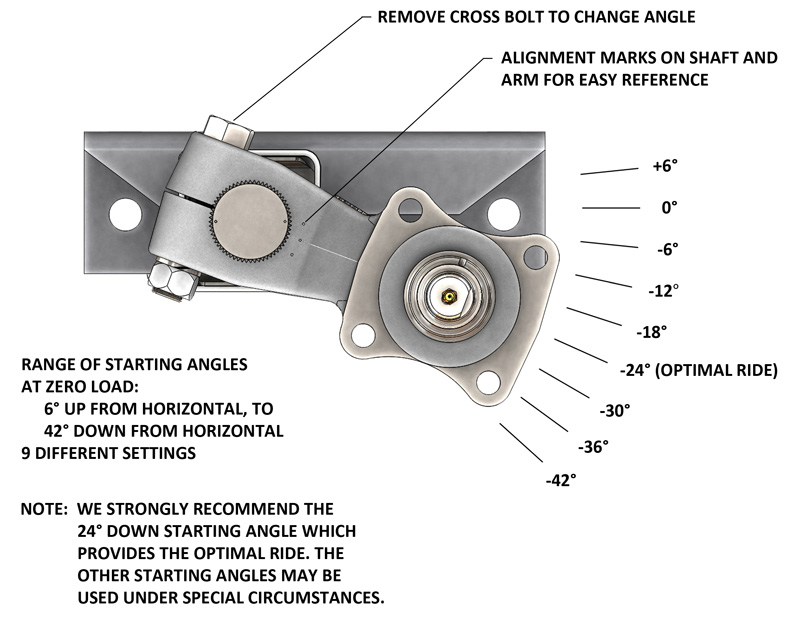

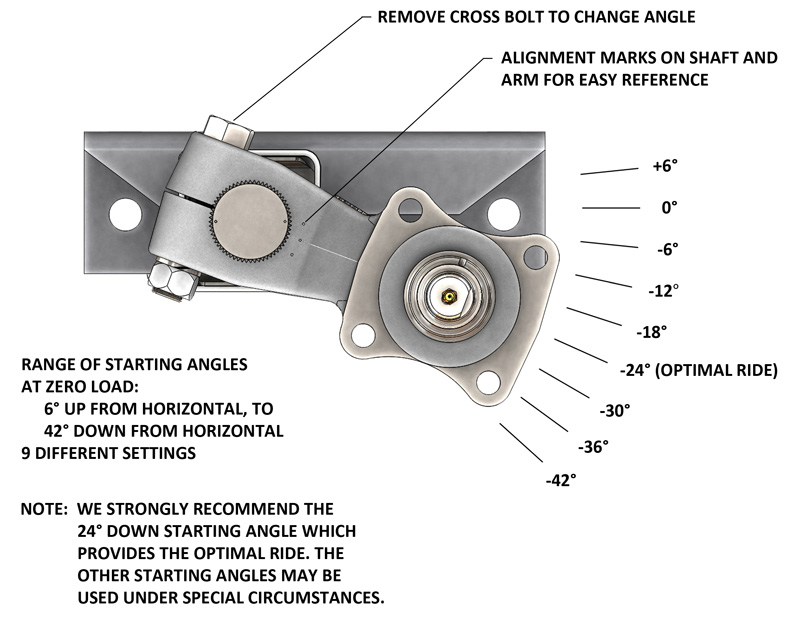

A unique feature of the Flexiride axles is that several are offered with an adjustable starting Angle. This attribute allows you to modify the ride height of your trailer. This makes their axles a more versatile replacement for traditional torsion axles that come with a fixed start angle.

Another versatile benefit of the Flexiride torsion axles is their two piece “half axle” design. At one time, replacing a torsion axle was a problematic process. Traditional torsion axle replacement demanded that the new axle be a perfect match in every way to the old one. Unlike leaf spring axles that have some fitment wiggle room, traditionally torsion axles came with pre-welded mounting brackets at a preset distance. Because of this, the axle’s mounting brackets were either a perfect match to mount to the trailer’s frame or it would be incompatible.

Flexiride axles are an excellent solution for a variety of trailer types as well. For people with utility trailers, the ability to weld the axle where you need it makes versatile enough to work on anything from a toy hauler to a log splitter.

For boat guys with a deep V Hull, the ability to weld the axle to your trailer eliminates the need to find a torsion axle with a drop “v” center. For those not already aware, when loading a boat with a deep hull, the axle must be “v” shaped in the center accommodate loading and off loading. By offering the axle as two pieces, Flexiride axles are able to bypass this issue altogether.

Flexiride axles are mounted to a trailer in two different ways. Axles between 425lbs and 3500lbs have a separate weld on plate that once attached, will provide the bolt on mounting point for the axle. Flexirides that are 5200lbs and greater must be welded directly to the trailer.

Trailer Parts Superstore is now offering a line of Nitrogen filled tires from LionsHead. These new tire and wheel combos are offered with either Steel or Aluminum rims. They are also available with either Castle Rock or West Lake ST tires. While we have always stocked a large variety of trailer tires, these tires represent an innovative and new option in our selection. For those not familiar, using pure Nitrogen provides a longer lasting and more durable tire. Lastly, LionsHead’s industry leading warranty program provides customers with new found peace of mind, which you can’t put a price on.

West Lake and Castle Rock tires are both manufactured using highly durable nylon and steel chords as well as premium rubber. They are offered exclusively in a Radial tread as opposed to Bias-Ply. They are sturdy and have proven themselves resistant against the most unforgiving road conditions. Both tires are an excellent option for any trailer application and were purposely created to withstand the demanding nature of towing. With their unique tread design and Radial fabrication they are able to maintain the maximum traction between tire and road, their benefits are only enhanced when paired with Nitrogen.

In spite of the fact that Nitrogen tires are a relatively new concept for trailers, it has been used in the tires of everything from construction equipment to automobiles. Nitrogen use is beneficial for a number of reasons. Traditionally, air filled tires were prone to a buildup of internal moisture. This is because while air does contain Nitrogen, it is actually about 78% Nitrogen, 21% Oxygen, and 1% other but contains a variable amount of water vapor. This moisture can enable internal tire rot, inadvertently leading to premature failure. Moisture buildup ceases to occur with Nitrogen. Because of Nitrogen’s purity, it is inert, noncombustible and non-corrosive and it is unaffected by changes in external temperature. This means that Nitrogen filled tires maintain a more consistent PSI for a longer period of time. Tires filled with Nitrogen can also provide upwards of a 10% increase in fuel economy and have been shown to reduce tire failure by 75%. According to the NITROFILL™ website, estimates put the enhanced tire life as high as 50%.

These tires carry a duel warranty from both LionsHead as well as NITROFILL™. LionsHead’s warranty provides coverage against manufacturer’s defects and any claims can be placed with them directly by providing specifications as well as photos of your tires damage. NITROFILL™ offers a comprehensive warranty that covers everything from replacement tires to towing as well as numerous other added benefits. Simply register your tires with NITROFILL upon purchase to take advantage of these benefits.

UFP (Unique Functional Products) is a popular manufacturer of axle and brake components for the marine trailer industry. UFP was recently acquired by the Dexter Axle Company, who has taken over their parts manufacturing. Just as the name implies, UFP parts are VERY unique. When compared to industry standards, their parts tend to be proprietary. Customers frequently contact us in need of assistance in replacing various UFP components. The intention of this blog is to clear up confusion when replacing UFP parts, and make things a little easier.

You will need calipers (Digital or Analog). A tape measure will not be sufficient in determining these diameters.

UFP hubs come in several configurations, different carrying capacities, and in both grease and oil bath style. Determine the bearing configurations first.

We can accomplish this in three different ways:

1) Measure the old Bearings:

After removing the bearings, measure the inside diameter of the bearings with your calipers. The most common sizes with UFP are the following.:

1.06 (1-1/16”), 1.38 (1-3/8”), 1.25 (1-1/4”) and 1.75 (1-3/4”).

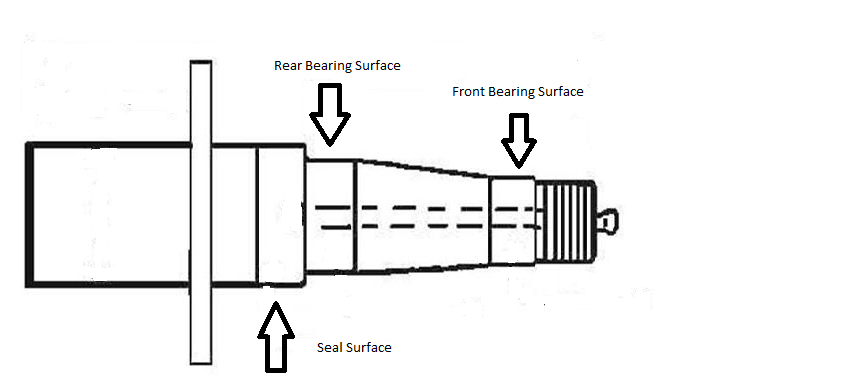

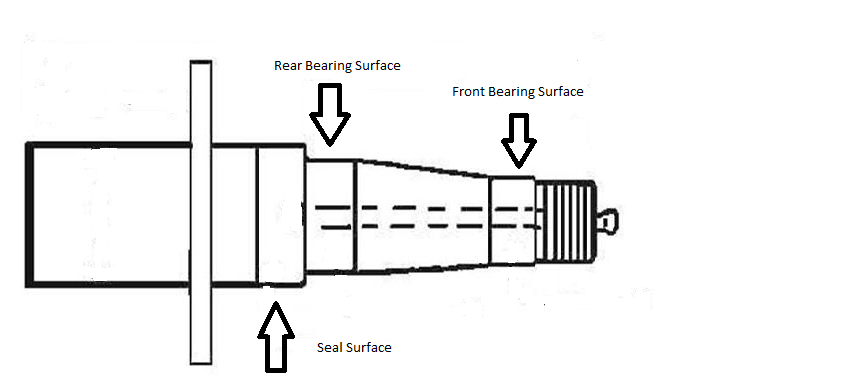

2) Measure the spindle itself:

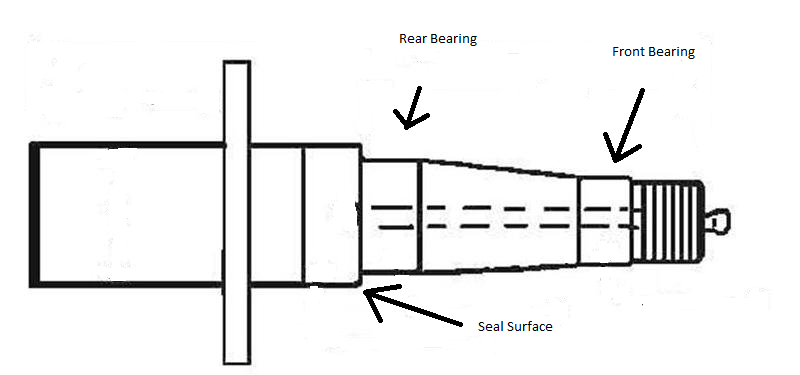

After removing the hub, using our calipers, measure the front bearing and rear bearing surfaces. Don’t be concerned if your spindle doesn’t appear the same as the sample photo below — these measurements will determine everything we must know.

If the bearing surface measures between 1.058 and 1.061, you have a 1-1/16” bearing.

If the bearing surface measures between 1.36 and 1.39, you have a 1-3/8” bearing.

3) Find the reference number:

The bearing reference numbers are stamped into your bearings. Below is a cross reference table of various bearing sizes:

| Bearing Reference Number |

Bearing Inside Diameter |

Bearing Inside Diameter |

| L44649 |

1-1/16″ |

1.06 |

| L68149 |

1-3/8″ |

1.38 |

| 14125 |

1-1/4″ |

1.25 |

| 25580 |

1-3/4″ |

1.75 |

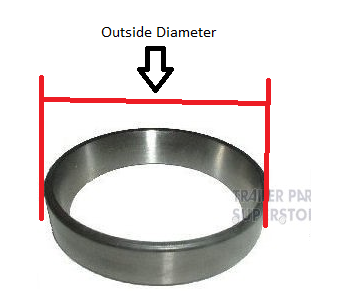

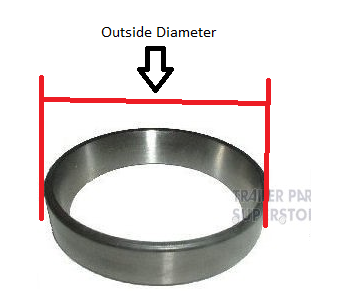

So now that we’ve made it this far, there’s another unique UFP topic to discuss. UFP uses a race smaller than industry standard with their 1-3/8” bearing. Using calipers, measure the outside diameter of the race. The Industry Standard size is 2.56. The UFP standard size is 2.328. If you’ve attempted to install a race and just can’t get it to fit, this may be why.

Just like bearings, the stamped reference numbers in the races determine their size. See the reference chart below for clarification.

Race Reference Number Race Outside Diameter Corresponding Bearing

| Race Reference Number |

Race Outside Diameter |

Corresponding Bearing |

| L44610 |

1.98 |

L44649 (1-1/16″) |

| L68111 |

2.56 |

L68149 (1-3/8″) |

| L68110* |

2.328 |

L68149 (1-3/8″) |

*Denotes UFP smaller than standard

Replacing your seal

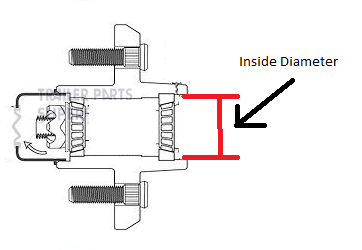

The final hurdle to overcome is replacing your grease/oil seal. There are two ways to accomplish this.1) Measure the old seal After removing the seal from the hub, you’ll use calipers for two measurements: the Inside Diameter and the Outside Diameter: 2) Measure the spindle and hub:

2) Measure the spindle and hub:

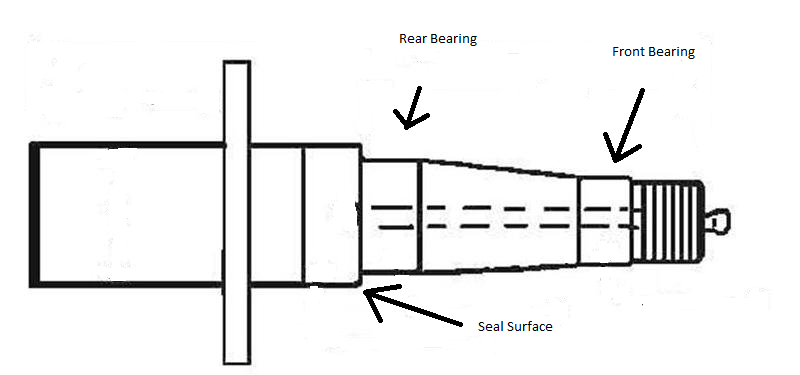

Oftentimes when you need to replace your seals, it’s after a mechanical failure on the road. These events are often unforgiving on the old seal and bearings, and measurements from the seal are just not a possibility. In order to determine the Inside Diameter of the seal, measure the diameter of the spindle’s seal surface as seen in the diagram below:

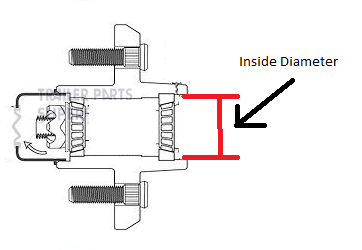

To determine the Outside Diameter of the seal, we will measure the Inside Diameter of the hub itself:

To determine the Outside Diameter of the seal, we will measure the Inside Diameter of the hub itself: So you made it this far, congratulations! You can also apply these methods to replace UFP Torsion arms and Rotors. As always, if you need further clarification or just want to talk about this with one of our technicians, we can be reached at 1-800-453-7379.

So you made it this far, congratulations! You can also apply these methods to replace UFP Torsion arms and Rotors. As always, if you need further clarification or just want to talk about this with one of our technicians, we can be reached at 1-800-453-7379.

2) Measure the spindle and hub:

2) Measure the spindle and hub: To determine the Outside Diameter of the seal, we will measure the Inside Diameter of the hub itself:

To determine the Outside Diameter of the seal, we will measure the Inside Diameter of the hub itself: So you made it this far, congratulations! You can also apply these methods to replace UFP

So you made it this far, congratulations! You can also apply these methods to replace UFP