The New Year is upon us and with a few nice days in the forecast, it’s a great time to work on those trailer problems we’ve all been putting off. With this in mind, I would like to highlight some parts for the guys out there towing livestock trailers. If you’re looking for brakes, axles, springs or simply seeking a way to keep things a little more tidy, our livestock parts selection will fit the bill.

Livestock and Agricultural trailer parts bring their own set of unique characteristics to the table. As any experienced rancher or farmer is already aware, maintaining your trailer is the first line of defense in safe towing. Whether you’re a green horn or you’ve been transporting livestock for years, we know you like to get things right the first time and we’re here to make sure that happens.

We know how critical functioning brakes are to a trailer, that’s why we offer a full line of Dexter electric brakes in a variety of sizes, braking power and even in manual and self-adjusting configurations. We also offer replacement parts to repair your existing brake assemblies.

In addition to backing plates and parts, we also stock a large offering of brake drums to pair with your brake assemblies. They are offered in both electric and hydraulic styles. There is a variety of weight capacities, bolt configurations and even a few de-mountable options.

Trailer Parts Superstore also stocks a large selection of axles for your livestock trailer. They come in a variety of lengths, drops, weight capacities and even a few fully assembled configurations. Depending on the carrying capacity and size, we can generally fill your axle needs with our in stock inventory.

We know how prone gates and gate hardware can be to damage after years of hard use. We offer a comprehensive selection of gates in different lengths and widths. We even stock a few aluminum gates for light weight options! We also stock numerous replacement parts, everything from hinges to replacement latches. Be sure to check out our gate lift assist kits while you’re browsing.

Trailer Parts Superstore is now a ‘Factory Direct’ parts center for CARRY-ON brand utility & dump trailers. Save on dozens of O.E.M. trailer parts for your Carry-On Trailer in our Delaware showroom, or online at: CARRY-ON PARTS

Carry-On Trailers are American Owned and American Built. They are the number one trailer builder by volume. Carry-On has corporate headquarters in Lavonia, Georgia and 7 manufacturing facilities strategically located throughout the country. They offer utility, cargo, horse, livestock, and specialty trailers.Carry-On trailers meet or exceed all government regulations and are compliant with standards set by our trade organization, the National Association of Trailer Manufacturers.

Eastern Marine is now offering BRI-MAR trailer parts! That’s right, get your factory replacement BRI-MAR trailer parts and more at http://www.easternmarine.com/bri-mar-dump-trailer-parts

Eastern Marine is now offering BRI-MAR trailer parts! That’s right, get your factory replacement BRI-MAR trailer parts and more at http://www.easternmarine.com/bri-mar-dump-trailer-parts

BRI-MAR Trailers has been providing the industry with high quality Hydraulic Dump Trailers for over 20 years. All of their dump trailers are manufactured in the USA and they are especially proud to meet or exceed all standards for quality and safety in the industry.

BRI-MAR has been a long term member of the National Association of Trailer Manufactures (NATM) and the North American Trailer Dealer Association (NATDA) and meets or exceeds all standards for quality and safety across their product lines.

Keep your trailer original with all O.E.M. parts. For a complete list of the brands we offer please visit EasternMarine.com

Posted Under:

Utility Trailer

This post was written by

ghoj on June 7, 2016

Comments Off on BRI-MAR Trailer Parts Store

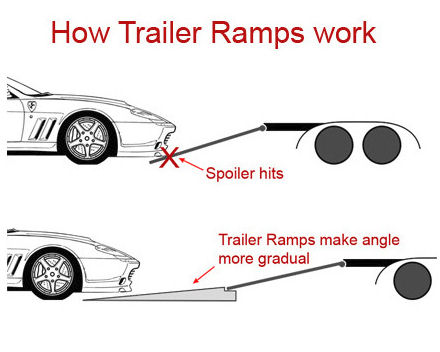

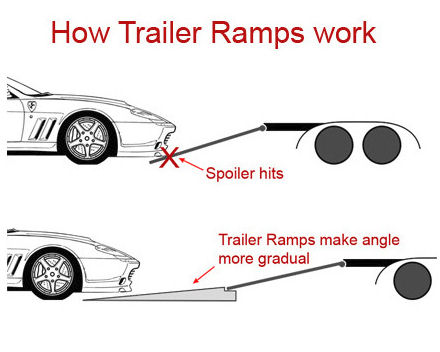

Race Ramps trailer ramps make loading and unloading low profile vehicles and equipment a stress free task. The end of the ramp is notched to seat your trailer ramp easily and securely. The added distance the Race Ramps provide allow for an incredible decrease in the approach angle for what is being loaded. This is perfect for any car show enthusiast that has a lowered or exotic car that they haul and worries about damaging the front or “bottoming out” when taking the vehicle on and off the trailer.

Race Ramps trailer ramps make loading and unloading low profile vehicles and equipment a stress free task. The end of the ramp is notched to seat your trailer ramp easily and securely. The added distance the Race Ramps provide allow for an incredible decrease in the approach angle for what is being loaded. This is perfect for any car show enthusiast that has a lowered or exotic car that they haul and worries about damaging the front or “bottoming out” when taking the vehicle on and off the trailer.

In the past many people used either a cut 2×4 or 2×6 to prevent scrapping during loading and unloading. The problem with wood is that it can age and weaken over time. The wood you get at a store also doesn’t have a weight rating which forces you to guess what would be appropriate for your need. With  race ramps the composite material is both lightweight and strong so it will greatly outlast the life of a wooden board. Each Race Ramp will also have a weight rating giving you the confidence that it will never fail while loading and unloading. Unlike the wood alternative Race Ramps have a no-skid bottom so you never have to worry about sliding or shifting while loading and unloading.

race ramps the composite material is both lightweight and strong so it will greatly outlast the life of a wooden board. Each Race Ramp will also have a weight rating giving you the confidence that it will never fail while loading and unloading. Unlike the wood alternative Race Ramps have a no-skid bottom so you never have to worry about sliding or shifting while loading and unloading.

Posted Under:

Uncategorized

This post was written by

ghoj on April 21, 2016

Comments Off on Race Ramps!!

| Hub Centric Wheels are centered by the center bore of the wheel and the hub flange. |

Lug Centric wheels are centered by the torque of the lug bolts; rather than the hub flange. |

|

|

There are two distinct types of wheels found on today’s Cars, Light Trucks, RV’s and Trailers. There are Hub Centric wheels and there are Lug Centric wheels.

The most common automotive wheels are Hub Centric in design. The center hole of these wheels is the actual center bore of the wheel. These wheels can be properly mounted and accurately balanced using the standard cone system supplied with most off car computer balancers.

Many of today’s RV & Trailer wheels are Lug Centric in design. The center hole of a Lug Centric wheel is not the true center. These wheels cannot be accurately balanced using the normal automotive cone wheel balancer mounting system in use by most repair shops.

Many Lug Centric wheels may appear to be mounted correctly with the center cone system, but they cannot be accurately balanced. The wheel balancer will continue to either “chase weights” or the wheel will show signs of imbalance when re-mounted on the RV or Trailer.

To ensure an accurate balance, Lug Centric wheels must be mounted on the balancer through their lug bolt pattern. Lug Centric wheels, when mounted on the RV or Trailer, are centered by the torque of the lug bolts and not the center bore of the wheel.

The only way to properly balance Lug Centric is through their lug bolt pattern. This style wheel must be mounted to the computer balancer in the same manner as it is mounted on the vehicle…through the lug bolt pattern.

Lug centric mounting on the wheel balancer mimics the way the wheel is mounted to the vehicle. If you are balancing Lug Centric wheels, you must use an Atlas Universal Adaptor ™ or similar devise. The standard cone system will not work properly.

Protecting your snowmobile trailer from wear and tear during heavy usages is just as important as protecting you Snowmobile. There are a few companies out there that make snowmobile trailer accessories designed to protect and secure. Two companies leading the charge in innovation and quality are Caliber Products and SuperClamp.

Caliber Products manufactures products focused on maintaining the trailer deck and ramp while  making it easier to load and unload snowmobiles. Their products usually help aid in gripping or gliding depending on where the item is designed to be used. Glide products are designed to help the Skis’s slide on and off the deck without damaging the wood while the Grips are there to help the track grab the floor while protecting what is underneath. Grips and Glides both come in varying thickness, sizes and patterns so chances are the right combination can be found to fit any application.

making it easier to load and unload snowmobiles. Their products usually help aid in gripping or gliding depending on where the item is designed to be used. Glide products are designed to help the Skis’s slide on and off the deck without damaging the wood while the Grips are there to help the track grab the floor while protecting what is underneath. Grips and Glides both come in varying thickness, sizes and patterns so chances are the right combination can be found to fit any application.

SuperClamp’s products are designed to aid in the securing of snowmobiles on the trailer for transportation to and from the trails. Their products include tie downs that will secure the rear or front of any snowmobile. Front and Rear tie down systems are designed to be quick and easy to use without sacrificing strength. It is also possible to add a padlock to these systems to add further security if snowmobiles are stored on trailer or sometimes left unattended.

SuperClamp’s products are designed to aid in the securing of snowmobiles on the trailer for transportation to and from the trails. Their products include tie downs that will secure the rear or front of any snowmobile. Front and Rear tie down systems are designed to be quick and easy to use without sacrificing strength. It is also possible to add a padlock to these systems to add further security if snowmobiles are stored on trailer or sometimes left unattended.

At the end of the day maintaining or protecting the trailer used to transport the snowmobiles is just as import as the snowmobiles them selves. The last thing anyone wants is to have to fix a broken trailer instead of hitting the trails.

It’s that time of year again to start thinking about winter activities and preparing for the season. One of the more popular winter activities is snowmobiling. Often not thought about until it’s too late, similar to boating, the trailer is a key supporting piece to the fun. If something brakes or malfunction’s on the trailer it has the potential for some pretty serious consequences. Luckily with our OEM parts, as well as aftermarket parts, you should be able to avoid preventable issues.

It’s that time of year again to start thinking about winter activities and preparing for the season. One of the more popular winter activities is snowmobiling. Often not thought about until it’s too late, similar to boating, the trailer is a key supporting piece to the fun. If something brakes or malfunction’s on the trailer it has the potential for some pretty serious consequences. Luckily with our OEM parts, as well as aftermarket parts, you should be able to avoid preventable issues.

Along with the standard parts we have always carried; tires, wheels, axles, and so on, we now carry factory direct parts specifically for snowmobile trailers from Triton Trailers and Karavan Trailers. These parts include tilt bed hardware, coverall hardware, ski hold downs, and other hardware specifically found on snowmobile trailers. Some of these parts are small but important and may be worth having an extra in your tow box, such as a tilt bed pin.

We also carry everything that you would need to outfit your trailer to protect the longevity of the deck and ramp. We carry products from Caliber and SuperClamp that are designed to add traction and protection to the trailer. These products included deck slides, track grips, ramp/shields, and more that will greatly improve the ease of loading and unload snowmobiles.

Unique Functional Products, UFP as they are commonly known, offers two different series of disc brakes. They offer a DB-35 and a DB-42 and since the parts are not interchangeable it is essential to be able to identify what you have.

DB-35

The DB-35 visually appears more similar to an automotive caliper. It will have two mounting ears below the body to attach the caliper directly to the axle brake flange. The rotor is also identifiable but it can be a little more difficult. On the rotor/hub there will be a minimum

The DB-35 visually appears more similar to an automotive caliper. It will have two mounting ears below the body to attach the caliper directly to the axle brake flange. The rotor is also identifiable but it can be a little more difficult. On the rotor/hub there will be a minimum thickness of 17mm (MIN THK 17.0 MM) stamped on the inside of the back.

thickness of 17mm (MIN THK 17.0 MM) stamped on the inside of the back.

DB-42

The DB-42 is visually unique and consists of a thick caliper body that houses the piston, and a metal shroud that will house the pads. The DB-42 will have only one mounting bolt hole located in the center of the bleeder valve and brake line port. On the rotor/hub there will be a minimum thickness of 22.40mm (MIN THK 22.40 MM) stamped on the backside.

The DB-42 is visually unique and consists of a thick caliper body that houses the piston, and a metal shroud that will house the pads. The DB-42 will have only one mounting bolt hole located in the center of the bleeder valve and brake line port. On the rotor/hub there will be a minimum thickness of 22.40mm (MIN THK 22.40 MM) stamped on the backside.

Posted Under:

Trailer Brakes

This post was written by

ghoj on July 23, 2015

Comments Off on UFP DB-35 vs. DB-42

Trailer Parts Superstore® carries a wide selection of Factory O.E.M. trailer parts in addition to our large assortment of aftermarket equipment and accessories. Many parts on a trailer are made by their respective manufacturers such as “Wesbar” lights or “Stoltz” rollers. Although we carry those items, we also carry parts made specifically for the following trailer companies:

Trailer Parts Superstore® carries a wide selection of Factory O.E.M. trailer parts in addition to our large assortment of aftermarket equipment and accessories. Many parts on a trailer are made by their respective manufacturers such as “Wesbar” lights or “Stoltz” rollers. Although we carry those items, we also carry parts made specifically for the following trailer companies:

EZ-LOADER, LOADRITE, VENTURE, KARAVAN, MAGIC TILT , SHORELAND’R ,

ROAD KING and CONTINENTAL

Most boat trailer manufactures used parts unique to them which can make it hard to find some of these parts. These factory direct parts are OEM replacement parts and can be matched by OEM part numbers or by dimension and descriptions. We try to offer one of the largest selections of Factory O.E.M trailer parts out there. We currently carry factory direct parts from 8 of the leading boat trailer manufactures and are still adding more. Don’t forget to to check our complete list of Factory parts here, FACTORY PARTS PAGE , as we are constantly adding items.

Posted Under:

Uncategorized

This post was written by

ghoj on March 20, 2015

Comments Off on Factory O.E.M Boat Trailer Parts

The two main types of ELECTRIC BRAKE ASSEMBLIES for axles 7K and below are Forward Self Adjusting (FSA) and Manual adjusting. The difference between the two is that the forward self-adjusting brakes will adjust themselves as needed so that they are always at the optimum position. Manual brakes must be adjusted manually via the star adjuster on the back side of the brake assembly as needed. Due to the reduction of required maintenance, the FSA brakes are becoming a lot more popular.

It is important to be able to identify which type is already on your trailer so that maintenance or replacing is done correctly. This cannot simply be done by looking for a star adjuster because both types have that. The FSA brakes will have a wire that will run from about 9 o’clock to 1 o’clock. On the 1 o’clock side it will have a banjo looking fitting (shown to the left). The manual adjusting brake will not have this wire running across the inside of the assembly.

It is important to be able to identify which type is already on your trailer so that maintenance or replacing is done correctly. This cannot simply be done by looking for a star adjuster because both types have that. The FSA brakes will have a wire that will run from about 9 o’clock to 1 o’clock. On the 1 o’clock side it will have a banjo looking fitting (shown to the left). The manual adjusting brake will not have this wire running across the inside of the assembly.

Another way to identify between the two is the bottom spring. On an FSA brake assembly (shown above) the spring will be straight and wrapped around the adjuster. On a Manual adjusted brake assembly (shown to the right) it will be a curved spring below the adjuster.

Due to the way that these brakes operate we absolutely recommend being consistent through the trailer. It is NOT SAFE to run both types of brakes on the same axle. It is NOT RECOMMENDED to run both types of brakes on the same trailer (different axles) but if the brakes on each axle match, it is operable. Problems will occur if one side of the trailer is adjusting automatically and brakes on the other side are not.

A final thought about FSA brakes assemblies. It is important to keep in mind that FSA brakes are automatically adjusted to perform at their best. This means they may not last as long as manually adjusted breaks. This is because manually adjusted brakes, if not adjusted regularly, are not being used to there potential and the shoes wear slower.

Posted Under:

Trailer Brakes

This post was written by

ghoj on February 25, 2015

Comments Off on Self-Adjusting vs Manual Adjusting Electric Brakes

Eastern Marine is now offering BRI-MAR trailer parts! That’s right, get your factory replacement BRI-MAR trailer parts and more at

Eastern Marine is now offering BRI-MAR trailer parts! That’s right, get your factory replacement BRI-MAR trailer parts and more at