Converting old drum brake systems to updated disc brake systems is becoming more and more popular. There are several reasons for these conversions but the most prominent being that a disc brake system is just more efficient. Other reasons include ease of maintenance and the longevity of the system. There are three main components of the system.

Converting old drum brake systems to updated disc brake systems is becoming more and more popular. There are several reasons for these conversions but the most prominent being that a disc brake system is just more efficient. Other reasons include ease of maintenance and the longevity of the system. There are three main components of the system.

The first thing to decide when making the switch would be the type of actuator that best fits the application. There are two options for the actuator. First being the standard Surge activated hydraulic actuator. Second being an Electric activated hydraulic pump called an Electric over Hydraulic (EOH) actuator. The standard surge brake actuator is more applicable to single or tandem axle trailers rated at or below 7,000 lbs. While the EOH actuator is better suited for greater then 7,000 lbs applications.

The Second major thing to consider would be the brand/version of trailer disc brakes that you want to install. We have many different options available to fit different types of trailers. The two most popular brakes we have for Boat Trailers are Kodiak (Dacromet/Stainless) and the Tie Down Engineering ‘G5’. More popular brakes for an RV conversion would me the Kodiak (Dacromet) and the Tie Down Engineering Eliminator/Vented brakes.

The third and final component of the conversion would be the Brake Line Kit. The brake lines do not need to be replaced 100% of the time but with all the money being invested into a new system it is worth it to upgrade your lines. The most popular Brake line kits for both surge and EOH is the Tie Down Flexible brake lines. The flex lines are DOT approved for up to 3000 psi. and are the easiest to install. We also have a large assortment of AG coated steel and stainless steel line kits.

Posted Under:

Trailer Brakes

This post was written by

ghoj on August 27, 2013

Comments Off on Drum to Disc Brake Conversion

Summertime has come at last, a glorious time of cookouts and lounging by the pool in the blistering heat sipping on cool drinks. Some of us even weather the trip down to the beach on the packed highways and byways full of cars racing to get to the sand and the smell of salt water and fried food. What people don’t realize is that this is a truck driver’s worst nightmare. Roads full of cars bogging them down on their journey to pick up or drop off their scheduled load.

During the summertime the braking systems on tractor trailers take a beating. It isn’t just the ominous ‘gator’ with its glistening silver belted teeth waiting to eat your car tire that you need to worry about, it’s the tractor trailer who’s brakes suddenly decided to stop working on the trailer. Suddenly a fifty thousand pound wall is moving at you and the brakes only work on the tractor, effectively halving the stopping speed and power of one of these massive mountains of metal and fiberglass. Heaven only help you if you cut one off and his brakes don’t work, you won’t know what hit you.

Literally.

So what, as a driver, can be done about the brakes on trailers to keep them working consistently and effectively? First you should do your standard walk around pre-trip inspection, if you hear any leaks or see any visual damage done to either the red or blue airlines linking the truck and trailer together. Check your belly lines to see if there is any visual wear or if one of the springs has broken to let them drag. D.O.T. checks these lines first as well and who really wants that ticket?

If you hear any leaks around your trailer tandems, odds are it could be either a line going or coming from an airbag or brake chamber. The same can be said if you hear a leak coming from the red and yellow parking brake on your dash when the trailer is attached, this can many times be a brake chamber back-feeding out through the valve in the dash.

Your brake shoes and drums themselves need to be inspected as well as the slack adjusters and s-cams that keep them working properly. These can fail without there ever being an indication that there was a thing wrong in the first place. Always check to see any damage done.

Nobody wants to be faced with the decision to hit a car that cut them off or roll their trailer on the shoulder because the brakes decided not to work. Check everything, keep an eye on it even if you think it is perfectly fine.

Summer is supposed to be about beaches and relaxation, not accidents and regret. Do what you can now to keep yourself and everyone else happy and safe this summer!

Check your lights and tires, spray your lines and cross your fingers. The season of DOT Blitz is upon us again.

Check your lights and tires, spray your lines and cross your fingers. The season of DOT Blitz is upon us again.

Every year DOT pulls more drivers over and leaves them stranded on the side of the road or in a scale house, waiting on a repair shop to get a service truck out to them. In the end they wind up paying almost double what it would have cost just to fix it right the first time! Everyone dreads it and everyone waits until the last second to do something.

Get proactive!

Buy that ten dollar gladhand that will save you $200 in service calls when that angry or grouchy DOT officer pulls you over. No one wants to pay that amount of money for something so trivial, so why not take care of it when you can?

There are many ways to check what’s going on with your trailer that start with just a simple pre-trip check, all the way to having a shop walk around it and check it for you. The first place to start checking your lights, for example, would be to start with your pigtail. Check the connections and make sure there are no cuts in the line that visibly show wiring.

Sometimes it isn’t always the most difficult thing that knocks a light out of service. Always start at the front of the trailer and go backwards. You know your truck and you know how it reacts to the trailers that you haul, you know when things go wrong. A mudflap gets ripped off, a tire goes bald. If you wouldn’t ignore your truck then you shouldn’t ignore your trailer either! Trailers almost always have problems before the truck and when things go wrong they can damage the truck.

DOT officers are looking for your trailer, one light out, a mudflap missing, and a bald or blown tire. If they pull you over one small audible air leak could shut you down and it is almost unbelievable how often leveling valves are to blame for air leaks that ruin runs and tie drivers up for hours waiting for repairs.

Take the time now to avoid time lost later! You’ll thank yourself in the long run.

Check out the parts mentioned above and our entire Tractor Trailer Parts offering at Trailer Parts Superstore.

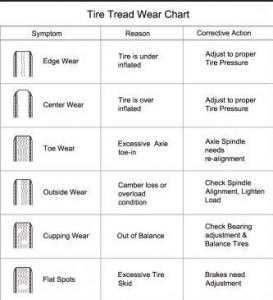

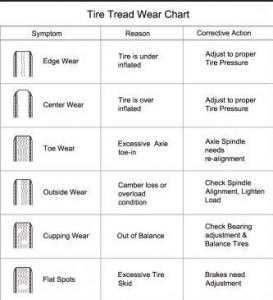

Unfortunately there is no simple answer. There are a multitude of problems that will cause uneven tire wear and sometimes it has nothing to do with the tire at all. It can be caused by anything from the hitch height on the tow vehicle all the way back to your suspension on the trailer. We will go over the most common issues that cause uneven tread wear and how to identify it.

Ball Height

Ball Height on the tow vehicle is a main factor in determining wither the trailer rides level or not. If the trailer is not towed level it can affect the load pressure on the tires. This is more important on a tandem Torsion Axle trailer because the two axles are independent of each other and will not transfer load between the two. On a torsion axle trailer you will find inside wear on the front axle if the ball is to low and inside wear on the rear if the ball is to high. If you have a single axle trailer or a leaf sprung trailer it is still important to have a level trailer but it shouldn’t affect tire wear.

Over/Under Loading

Trailer axles are design with specific cambers (or bends) that match the weight capacity of the axle. This is done to help the axle ‘flex’ into position when load is applied. The camber in the axle will flatten/level when the trailer is near or at the axle capacity. If the trailer is over loaded it can over camber the axle which will, over time, begin to wear the inside of the tires. If the trailer is under loaded over an extended period of time it can begin to wear the tires on the outside.

Tire Pressure

Trailer Tires (‘ST’ or ‘LT’) are designed and manufactured differently than car or truck tires. This can lead to some hesitance to inflate a ‘ST’ to the maximum pressure listed for the tire. Trailer tires should be inflated to the maximum pressure listed on the tire, which sometimes can me as high as 90- 110 psi. The tire is made to be able to hold the pressure as well as the fact that that pressure is needed to give the tire the carrying capacity that it is rated at. Under inflating a tire can cause not only a lower weight capacity but it can also cause wear on the outsides of the tire.

Broken Suspension/Bent Axle (Leaf Sprung trailer)

If you can eliminate all other issues that was discussed previously you can begin to check the trailer leaf springs or trailer axle. We put these two together because they are integrated systems on the trailer and is easy to check the both at the same time. It is best to let the tire tell you where to begin your search. Look at the tires and localize the wear, example: right side tire with inside wear, or both tires inside wear. Once you have the area localized first check leaf springs. The center bolt on the leaf springs should both be equal distance from frame rail. If this is not the case the springs should be replaced. Also visually inspect leaf springs for any broken springs, bolts, or shackles. Once you can eliminate leaf springs from the issue it might be time to replace the axle.

Its that time of the year again to go through your pre-season trailer check list. There are several things to check or maintain on your trailer on an annual basis before the heavy usage begins. These things help to ensure the trailer is in tip top shape and most importantly safe. Most of the things that have to be done are easily over looked because they don’t seem important or maybe they seem redundant or hard to do. Here’s a simple check list to go through before each season that will help pro long the life of the trailer and help make it safer.

Its that time of the year again to go through your pre-season trailer check list. There are several things to check or maintain on your trailer on an annual basis before the heavy usage begins. These things help to ensure the trailer is in tip top shape and most importantly safe. Most of the things that have to be done are easily over looked because they don’t seem important or maybe they seem redundant or hard to do. Here’s a simple check list to go through before each season that will help pro long the life of the trailer and help make it safer.

Trailer Tires

Trailer tires are constructed differently than a standard passenger car tire and have to be treated differently. After sitting all winter it is good to check a couple different things with the tires. First thing to check is the tread of the tire. The tread of the trailer tire should be even depth across the width of the tire. If this is not the case it is usually an indication of an issue with axle or suspension (More on this to come). Side walls should also be checked to ensure there isn’t any cracking or deterioration. Next check the tires PSI, it is suggested to run ‘ST’ and ‘LT’ trailer tires at the maximum PSI listed on the tire. Finally check lug nuts to ensure none are loose.

Hubs

There are several different types of trailer hubs as well as lubrication systems available on the market. The best thing to do would be to remove hub/drum/rotor to repack bearings and check seal. This can be a lot of work depending on the set up so it’s often over looked. If this is something that is not going to get done that doesn’t mean nothing should be done. Most of the time (except drum brake applications) the rear seal can still be checked for leaks without removing anything. Also take advantage of the lubrication system being used to lube up (check owner’s manual or call us for specifics) and check old grease for any contaminants that could indicate an issue.

Electric Brakes

Electric Drum brakes should be checked to ensure that they are properly adjusted. Also check that the magnets are still functional and the best way to do that is to use the breakaway kit. Pull the pin on the breakaway kit and listen for the magnets. Once the pin is pulled you should hear the magnets humming. If this is not the case, then check out “Electric Brake Troubleshooting”.

Hydraulic Brakes

Short of bleeding the brakes and adjusting the (drum) brakes there is no fancy way to test them until you hit the road. What you can check is pad/shoe wear to ensure that they are still at safe levels. Also check for any leaks in the system and make sure master cylinder is full.

Lights

Lights are probably the most simple to check although it is easiest with help. With trailer plugged in to the tow vehicle check the running lights, brake lights, turn signals, and all marker lights. If there are broken or non working lights it might be a good time to up grade to LED lights.

Well, now that the warmer weather is starting to make it’s move into the central and northern parts of the country many folks are thinking of getting their towable boats & RV’s ready to roll for the season. There are many things on the “to do list” in order to get a trailer ready for the season. One of the most over looked things on that list is the trailer leaf spring, and there are a few reasons for this.

It is easy to over look trailer leaf spring maintenance because it is not something that needs to be done very often. Just because something does not require often or annual maintenance does not mean it should be over looked. Trailer leaf springs should be checked often to ensure that they are always in safe working condition.

Things To Look For:

-

-

Major Failure

-

-

Bad Bushings

-

-

Rusty Spring and Hardware

-

-

Broken Leaf, Exposed

-

-

Broken Leaf, Internal

If all of those things check out fine then your leaf springs should be good to go. Just make sure to go through the same check next time trailer maintenance is done. If there was an issue noticed and the springs need to be replaced, that job is probably easier than you might think.

Replacing Leaf Springs

First thing to do is to identify which type of Trailer Leaf Spring you have and the proper way to measure it. Once you have the correct replacement spring and all the proper hardware on hand its time to begin the job. Remove Weight from springs and axle by jacking up the trailer (All trailers and situations are different so please use the safest way to do this, Jack stands and Wood Blocks work great).

With the trailer in the air and the axle lightly supported, remove the U-bolts being used to attach the leaf springs to the axle. Keep in mind that gravity will come into play if the tires are off the ground they will drop to the ground when those bolts are removed. The shackle bolts can now be removed from the hanger and spring which should now release the spring. Reverse process to install new leaf springs, bushings and shackle bolts.

Tips:

- We always like to stress safety so it goes with out saying that most of this job should be done without putting any major extremity under the trailer.

- It is a perfect opportunity to replace the Tie Plate Kit ($20-$30 Well Spent)

- Get a Helper, It can be a one man job but it is a lot easier with help.

- If you have a question, Call Us, Don’t Guess!!! 1-800-453-7379

- Amount of Leafs does NOT automatically dictate weight capacity. Always pick your Springs based on the weight cap. and not the amount of leafs

Tire Storage Tips

A few simple winter storage procedures can go a long way in adding years of service life to your trailer tires. Quite often overlooked while performing winterization of Boats or Campers are the trailer components that keep your rig going safely down the road. The rubber trailer tires are especially susceptible to premature weather damage if not properly maintained during long periods of inactivity.

Check out all of our trailer tires & tire accessories online at: TrailerTires.com

Here is a ‘Short List’ of some tips to consider for proper trailer tire storage:

1) Keep tire pressure at or slightly below the rated maximum PSI listed on the sidewall

2) Place a 10 x 7 or similar concrete paver under each tire if it is to be stored on non-paved surfaces

3) Make sure the valve stem interior is free of dirt, and always use a valve stem cap

4) Cover the tires with Storage Covers to keep out damaging UV sunlight

5) If practical, jack up trailer so that tires are just off the ground and support under frame rail (not under axle)

Posted Under:

Trailer Tires & Wheels

This post was written by

ghoj on November 30, 2012

Comments Off on Winter Storage Tips for Better Trailer Tire Life

Metric Trailer Bearings

Trailer Parts Superstore is now offering a selection of

METRIC sized trailer axles, wheel bearings, grease seals, dust caps and complete hub kits.

The 25mm trailer bearing is just a little smaller then a 1″ bearing, and is becoming more common on light-duty trailer applications in the United States. Initial uses were seen on little red Utility trailers imported from China by mass merchants such as Harbor Freight. More recently, domestic boat trailer manufacturers such as Venture Trailers have started to use Metric size axle spindles & bearings on some of their light weight boat trailers.

The 25mm metric trailer bearing is not readily available, so having a spare set or even a complete wheel hub on hand for roadside emergencies could save your day.

CLICK HERE to check out our selection of metric sized trailer axles, hubs, grease seals & wheel bearings.

Karavan Boat Trailer Parts

New product line announcement at Eastern Marine ~ Trailer Parts Superstore: KARAVAN Boat Trailer Parts including bunk & roller brackets, factory axles, fenders and a bunch of other KARAVAN brand name repair parts unique to their boat trailers now in stock!

CLICK HERE to see our offering of KARAVAN Trailer Parts

Posted Under:

Uncategorized

This post was written by

ghoj on September 25, 2012

Comments Off on KARAVAN Boat Trailer Parts Now In Stock!

UFP Trailer Parts

New product line announcement at Eastern Marine ~ Trailer Parts Superstore: UFP Trailer Parts (Unique Functional Products) include the Trailer Buddy disc brake system, trailer brake actuators and a bunch of other UFP brand repair parts unique to boat trailers now in stock!

Check out the UFP Trailer Brakes at http://www.easternmarine.com/UFP-Trailer-Disc-Brakes/

Or

CLICK HERE view our entire UFP Product Offering

Posted Under:

Trailer Brakes

This post was written by

ghoj on June 7, 2012

Comments Off on UFP Trailer Parts Now In Stock at Trailer Parts Superstore

Converting old drum brake systems to updated disc brake systems is becoming more and more popular. There are several reasons for these conversions but the most prominent being that a disc brake system is just more efficient. Other reasons include ease of maintenance and the longevity of the system. There are three main components of the system.

Converting old drum brake systems to updated disc brake systems is becoming more and more popular. There are several reasons for these conversions but the most prominent being that a disc brake system is just more efficient. Other reasons include ease of maintenance and the longevity of the system. There are three main components of the system.

Its that time of the year again to go through your pre-season trailer check list. There are several things to check or maintain on your trailer on an annual basis before the heavy usage begins. These things help to ensure the trailer is in tip top shape and most importantly safe. Most of the things that have to be done are easily over looked because they don’t seem important or maybe they seem redundant or hard to do. Here’s a simple check list to go through before each season that will help pro long the life of the trailer and help make it safer.

Its that time of the year again to go through your pre-season trailer check list. There are several things to check or maintain on your trailer on an annual basis before the heavy usage begins. These things help to ensure the trailer is in tip top shape and most importantly safe. Most of the things that have to be done are easily over looked because they don’t seem important or maybe they seem redundant or hard to do. Here’s a simple check list to go through before each season that will help pro long the life of the trailer and help make it safer.