What Causes Uneven Tread Wear?

Unfortunately there is no simple answer. There are a multitude of problems that will cause uneven tire wear and sometimes it has nothing to do with the tire at all. It can be caused by anything from the hitch height on the tow vehicle all the way back to your suspension on the trailer. We will go over the most common issues that cause uneven tread wear and how to identify it.

Ball Height

Ball Height on the tow vehicle is a main factor in determining wither the trailer rides level or not. If the trailer is not towed level it can affect the load pressure on the tires. This is more important on a tandem Torsion Axle trailer because the two axles are independent of each other and will not transfer load between the two. On a torsion axle trailer you will find inside wear on the front axle if the ball is to low and inside wear on the rear if the ball is to high. If you have a single axle trailer or a leaf sprung trailer it is still important to have a level trailer but it shouldn’t affect tire wear.

Over/Under Loading

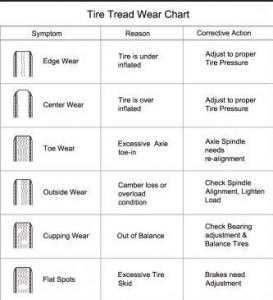

Trailer axles are design with specific cambers (or bends) that match the weight capacity of the axle. This is done to help the axle ‘flex’ into position when load is applied. The camber in the axle will flatten/level when the trailer is near or at the axle capacity. If the trailer is over loaded it can over camber the axle which will, over time, begin to wear the inside of the tires. If the trailer is under loaded over an extended period of time it can begin to wear the tires on the outside.

Tire Pressure

Trailer Tires (‘ST’ or ‘LT’) are designed and manufactured differently than car or truck tires. This can lead to some hesitance to inflate a ‘ST’ to the maximum pressure listed for the tire. Trailer tires should be inflated to the maximum pressure listed on the tire, which sometimes can me as high as 90- 110 psi. The tire is made to be able to hold the pressure as well as the fact that that pressure is needed to give the tire the carrying capacity that it is rated at. Under inflating a tire can cause not only a lower weight capacity but it can also cause wear on the outsides of the tire.

Broken Suspension/Bent Axle (Leaf Sprung trailer)

If you can eliminate all other issues that was discussed previously you can begin to check the trailer leaf springs or trailer axle. We put these two together because they are integrated systems on the trailer and is easy to check the both at the same time. It is best to let the tire tell you where to begin your search. Look at the tires and localize the wear, example: right side tire with inside wear, or both tires inside wear. Once you have the area localized first check leaf springs. The center bolt on the leaf springs should both be equal distance from frame rail. If this is not the case the springs should be replaced. Also visually inspect leaf springs for any broken springs, bolts, or shackles. Once you can eliminate leaf springs from the issue it might be time to replace the axle.