Trailer Stake Body Parts

Most flat bed trailers are used to haul lawnmowers, heavy equipment or other cargo that needs to be tied down safely. However, flat-beds are limited in their usage for general hauling of items that would not require tying down each piece of cargo. This includes loose items like cardboard boxes or even landscape refuse. To improve the flexibility of your truck or trailer, adding a stake body framework is a good idea.

The idea is to build “gate” sections that latch together to form a strong framework but are also quickly removable so the trailer can perform its other tasks. Stake bodies can be simple wooden structures or CAD engineered works of art designed to perform a specific task. If stake body is to be wood and the trailer has pre-installed stake pockets, the job becomes fairly straightforward and pocket position determines how the gates are constructed.

Important Stake Body Parts and Accessories

Starting on the long side of the bed, trim the appropriate number of 2×4 wood lumber, cut to the desired height and insert in the stake pockets on the frame of the trailer.

Bolt-On Stake Pocket, 3″ x 1-1/2″ ID #B2373G

The end of the wood being inserted in the pocket will have to be trimmed on all four sides to get a tight fit. Often, the wood is selected on its ability to withstand the elements, such as “treated“ lumber. These 2 x 4 boards will become the upright (or vertical) post assemblies for the stake body frame.

Select the length of the horizontal wood slats (such as 1” x 6”) that connects two of the uprights to make the first gate. The horizontal slat length should be set based on proximity to connect to the adjacent gate horizontal slats. Screw or bolt the horizontal slats to the vertical 2 x 4” stakes to complete each gate. For best results, be consistent in choosing the size and spacing of the horizontal slats for a professional appearance.

Each gate should be trimmed so that it lines up closely with the next gate. It will be linked to the next gate by specific interlocking hardware:

Straight Stake Rack Connector Set #6015

For improved stability of the gates and rigidity of the whole structure, the connecting hardware should be added to two different horizontal slats.

Corner Stake Rack connector sets can be used for mating two corner gates:

Corner Stake Rack Connector Set #6020

These types of connecting hardware will allow the middle gate of three to be easily lifted out of the way to load or unload cargo. However, the two outside gates of three will not be able to be removed unless the middle is removed. These can be set-up in different ways so that a specific gate will always be removed.

Or Stake Body Spring Loaded Latch w/Keeper #06035 can be used for easy removal of any gate. This is also a more safe option since it prevents gates from being jostled loose while traveling down the road.

Stake body conversions require a good bit of thought beforehand to determine the best configuration for your needs. The custom design approach will allow the proper parts to be ordered before the process begins.

Posted Under:

Utility Trailer

This post was written by

ghoj on May 21, 2012

Comments Off on ADDING A STAKE BODY TO A FLAT-BED TRAILER

Trailer Bunk Slicks

Many of our customers call Eastern Marine looking for ideas for easier loading and unloading their boats on their bunk trailers. These trailers are usually several years old and have the original carpeted bunk boards in place. Over time, the carpet absorbs dirt and contamination that causes increased drag on the boat hull. Hulls with greater weight will have greater drag. Their obvious choice is to replace the carpet or replace the bunk board. If the boards are solid, there are easier remedies for this problem.

1) ‘Liquid Roller Spray’ is a short-term fix that the customer can purchase. The bunk carpet should be scrubbed clean with detergent, rinsed and dry before use.

Liquid Rollers Bunk Spray Coating, 10 oz. #MK6810

2) A more elegant solution is the ‘bunk slicks’ product that can be fit over the un-carpeted 2×4 or 2×6 bunk boards. These bunk covers are made of a durable plastic, come with stainless steel mounting hardware and have received great customer reviews. They also assist in centering the boat while recovering. Be careful with these! Make sure the winch strap /cable is secured to the boat or it could slip off while backing down the ramp.

Self Centering Bunk Glide On’s for 2×6 Lumber (Black), #86295

Another similar option is the EZ-Slide Bunk Pads, also made from a durable plastic material. However, these have a lessor hull weight limitation.

EZ-SLIDE Bunk Pad Kit for 6″ Wide Bunks KIT4 #013.3

3) The last option would be to replace the bunk board and uses the same bolster/swivel bracket. They are only available in 4 or 5 ft. lengths and have a hull weight limitation of 1500 lbs per pair.

4ft Poly-Roller Bunk Assembly (1 pair) #86157

Check out the Trailer Parts Superstore to investigate these and other options to make loading / launching from a bunk style trailer faster and easier.

Posted Under:

Trailer Bunks

This post was written by

ghoj on April 30, 2012

Comments Off on IMPROVE BOAT LOADING ON BUNK TRAILERS

Rusty Trailer Parts

Owners of older trailers know that replacing the hardware like axle u-bolts, brake fasteners and lug nuts is a major chore. Boat trailers (especially salt water) are the worst- case scenarios. Below are some ideas on how to make this job easier.

PENETRATING FLUID

The Trailer Parts Superstore carries 3 different brands:

CRC Freeze-Off 11.5oz #05002

CRC Ultra Screwloose® Super Penetrant, 11oz. #05330

B’LASTER® PB Penetrating Catalyst, 11oz. #16PB

The most recognized of these is PB Blaster.

While scanning through some related websites the other day, I saw a thread that referenced a study done by the magazine “MACHINISTS WORKSHOP” comparing several commercially available products. The study was based on application of commercial penetrants on similar corroded hardware with the test measurement being wrench torque required to loosen the bolt. Amazingly enough, a 50% mixture of automatic transmission fluid and acetone tested the best by far. Take your favorite penetrant and apply to hardware for several days in a row

HAND TOOLS

The best thing to use is a long handled breaker bar with the appropriate socket. The long handle will allow more torque on the corroded hardware than a short handled ratchet. If the bolt will not release, it may be possible to snap off the bolt.

POWER TOOLS

I have had success with a reciprocating saw (sawzall) but an electric or air grinder or cutting tool may be better and safer.

REPLACEMENT HARDWARE

Try to use galvanized or stainless steel hardware to prevent premature corrosion.

These penetrating fluids and many replacement hardware items are available on Trailer Parts Superstore

Posted Under:

Uncategorized

This post was written by

ghoj on February 29, 2012

Comments Off on REMOVING RUSTY TRAILER HARDWARE

Snowmobiles are extremely popular in the cold weather regions of North America such as the northern United States, Canada and Alaska. Caliber Trailer Accessories is a company that has devoted much development time to engineering products to make the trailering aspect of this sport easier for its devotees. Located in Burnsville, MN, many of the employees are Power-sports enthusiasts and this passion has driven product development efforts in this niche of the trailer industry. The company views itself as experts in Plastics for the Power-Sport market and actually modifies some materials for their end use. Caliber primarily deals with products for after market use but also participates in OEM applications and also has products for boat trailers.

Their products for the Snowmobile ATV trailer market are made from high-density polyethylene HDPE. They have tweaked their material to be “impact modified” for durability and therefore can offer a limited lifetime warranty on their products. These products are fastened to the decks and ramps of customer trailers and are classified as “Glide” for snowmobile runners and “Traction” for ATV and multi-use. Using these products will extend the life of the wooden trailer decks and make loading and unloading much easier for the customer. Below is a description of the Caliber Trailer Deck Products:

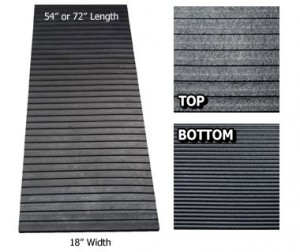

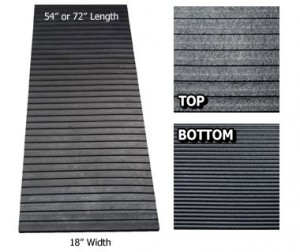

TraxMat

1) Designed specifically for snowmobile track traction

2) Leading product on the market – made from durable HDPE

3) Allows deck to drain and dry underneath

4) 18” wide and offered in 54 and 72” lengths

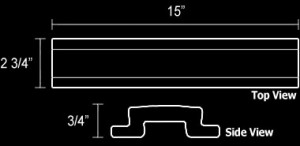

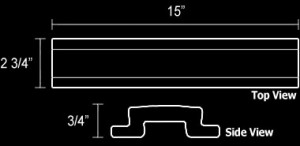

Track Grip System

1) Basic grip system for ATV and snowmobiles

2) Low Cost Option – older product – made from HDPE

3) Great for tilt trailers and trailer ramps

Grip Dimensions:

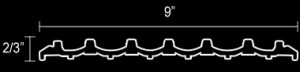

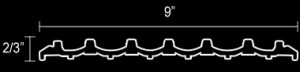

LowPro Grip/Glides

1) Made from HDPE; stainless steel mounting hardware included

2) Designed for ATV/Snowmobile Combination Trailers

3) Used as grips for ATVs and glides for snowmobiles

4) 9” wide for 14” ski stance variation

5) Holes in top to allow mud to clear the deck after washing

6) Sold in 30” lengths

GripGlides

1) Grips for ATV tires

2) Glides for Snowmobile wear bars

3) Great for 10’ tilt trailer

4) Lower cost option

5) Also available in a ramp configuration

LowPro Glides

1) Constructed from HDPE to protect the trailer deck from carbide wear rods

2) One of the early products developed by Caliber

3) For easy loading / unloading of snowmobiles

4) 6” or 8” wide to accommodate any brand of snowmobile

6) Wear rods ride on top of channels

7) Extension kits available

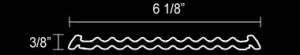

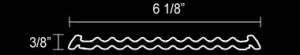

MultiGlides

1) Constructed from HDPE for durability and most popular glide-only product

2) Snowmobile wear bars slide into the designed channel spacing

3) Designed to allow the snowmobile carbide wear bar to suspend above the plastic

4) Significantly reduced drag while loading / unloading

5) Channel spacing will work for approx. 95% of snowmobiles

6) Available in 6-1/4” and 8-1/4” wide

Caliber makes many other accessories with the same theme and makes a strong effort for Constant Improvement of its products. It is refreshing to see an American company study a small part of the trailer market and develop materials and products that make the difficult part of Power Sports (trailering) much easier. These and many more Caliber products can be found on the Trailer Parts Superstore

Posted Under:

Powersport Trailer Equipment

This post was written by

ghoj on January 30, 2012

Comments Off on Snowmobile Trailer Deck / Ramp Glide Pads & Traction Mats

Boat, Utility, RV & Commercial Trailer Parts

Well, the year is almost over and the staff here at Trailer Parts Superstore would like to wish you and your loved ones a very safe, healthy & happy New Year in 2012.

With cold weather covering the upper two thirds of the U.S. many of our recreational customers have put their Trailers, Boats and Recreational Vehicles into storage for the winter months ahead. Proper winterizing and covering practices can keep your equipment protected during long periods of inactivity, and also make re-commissioning much easier come springtime.

In addition to offering a huge selection of tarps & semi-custom covers, Trailer Parts Superstore also offers a wide selection of Winterizing Products to help you get your equipment properly perpared for a long winters rest.

For those lucky enough to be able to use their Snowmobiles, Boats or RV’s during the coming months we want you to know that Trailer Parts Superstore keeps a full inventory on-hand of the items we stock year round at our Delaware distribution facility.

Best wishes from the staff at Trailer Parts Superstore !

Posted Under:

Uncategorized

This post was written by

ghoj on December 14, 2011

Comments Off on December 2011 Trailer Parts Superstore Year-End Update

Boat, Utility, RV & Commercial Trailer Parts

Eastern Marine / Trailer Parts Superstore is pleased to announce the recent launch of an entirely new, more secure website for your enhanced shopping pleasure.

Eastern Marine has partnered with Geo-Trust, Authorize.Net and FineLine Websites to provide you with an improved shopping experience that provides enhanced security. Our new website exceeds standards developed by the Banking Credit Card Industry for your added protection. We believe that shopping online should be a pleasure, not a risk!

In addition to these improvements we now have a much simpler, quicker checkout system, an enhanced site search tool to help you find what you’re shopping for fast, and best of all an entire suite of order history / tracking information for customers who choose to create an online account at any of our websites. Check it out today by clicking on ‘My Account’ near the top of our site and create your very own customer profile for an enhanced shopping experience.

We hope you enjoy our upgraded websites and shopping system and welcome your comments or suggestions using the ‘Contact Us’ button at TRAILER PARTS SUPERSTORE.

Posted Under:

Uncategorized

This post was written by

ghoj on November 23, 2011

Comments Off on Trailer Parts Superstore Upgrades Online Shopping System

Snow Plow Repair Parts & Salt Spreaders

In an effort to continually present useful new products to our customers, Eastern Marine has added Snow Plow replacement parts and Salt Spreaders to our catalog and showroom. The snowplow parts were added during the 2010 season and Salt/Sand Spreaders added in 2011.

The Snow Plow Aftermarket (S.A.M.) parts are available for Meyer, Western, Diamond, Fisher, Sno-Way, Blizzard & Boss products. The electrical parts include switches, controllers, motors, cables, coils and others. Mechanical/Hydraulic parts include valves, cylinders, sectors, cut edges, deflectors and others. Most of these products are available at our newark, DE showroom with few exceptions. All items can be shipped to the continental United States and express shipping is usually available for those ‘must have’ situations.

http://www.easternmarine.com/Snow-Plow-Parts-Accessories/

Based on customer feedback, Eastern Marine decided to offer the SALTDOGG® Salt / Sand Spreaders. This wide range of items start with Manual (Walk Behind) in several capacities, Tailgate mount, Under Tailgate mount, gas and electric Pick-up bed hoppers up to stainless steel Municipal truck size 16 yard capacity.

Salt Spreaders & Spreader Parts

In order to satisfy our customers, Eastern Marine will continue to investigate and add interesting and useful items to our product offerings.

Posted Under:

Snow Plow Parts

This post was written by

ghoj on October 7, 2011

Comments Off on EXPANDED OFFERING: Snow Plow Parts & Salt Spreaders

Here, at the Trailer Parts Superstore, we often get calls from frustrated customers who have found out that their trailer has been outfitted with a suspension salvaged from a mobile home transport. A little history: when mobile homes were first being introduced, some of the builders asked the Dexter Axle Co. to develop a low cost suspension system for limited use only for the transport of the mobile homes of the day. Dexter developed a suspension that was accepted and was in wide use during the heyday of the mobile home. This system was not approved by DOT, but approved by HUD (Housing and Urban Development). It was called the MHA (Mobile Home Axle) and was supposed to be disposable. Unfortunately, opportunists would salvage these suspensions and re-use them on old trailers and even new trailers.

This suspension consisted of an axle with drum brakes and springs. Even though the axle could be rated at 6000lb, the spindle, bearings and hub de-rated it to 4500 lb. The brake assembly backing plates were welded to the spindle and they could be rebuilt but not replaced. Brake rebuild parts can still be ordered directly from Dexter. The springs were a low quality mono-leaf and can be replaced with a 25.25” double eye leaf spring.

25-1/4″ Double Eye Trailer Leaf Spring (4 leaves) #US-1067

The inner bearings are 68148

Timken® 1-3/8″ Bearing Cup & Cone Set #17

and the outer bearings are 67048

Timken® 1-1/4″ Bearing Cup & Cone Set #6

The wheel that is used is called the “Demountable” rim.

Demountable Trailer Wheel Rim and Tire

with a tire like this:

LOADSTAR 8-14.5″ LT Heavy Duty Tire, Load Range G

and matches with the Demountable Brake Drum

DEXTER 12″x2″ 5-Spoke Wheel-Drum Kit: Demountable 6k UTG Axles

that mounts with

DEXTER Rim Clamp for Demountable Drum

Dexter Axle also developed a more flexible system called the MHU (mobile home utility) that allowed users to change to standard drums and wheels and used replaceable Brake assemblies. This system was rated at 6k, had larger bearings more expensive and not as prevalent in the market place as the MHA.

Tie Down Engineering recommends changing brake fluid every two years for marine trailers and every three years for utility trailers.

Tie Down Engineering recommends changing brake fluid every two years for marine trailers and every three years for utility trailers.

Brake fluid is one of the most neglected fluid in vehicles today, yet is vitally important for safe towing. Consequently, trailer owners should check the fluid in both the tow vehicle and the trailer on a regular basis. The brake fluid should be changed if it is contaminated. The issue is that old brake fluid may not be safe if moisture contamination is above a certain level.

Many experts have long recommended changing the brake fluid every year or two for preventative maintenance. Their rationale is based on the fact that glycol-based brake fluid (DOT 3 & 4) starts to absorb moisture from the moment it is put in the system. The fluid attracts moisture through microscopic pores in seals and exposure to the air. The problem is obviously worse in wet climates where humidity is high and with marine trailers constantly subjected to dunking in lakes, rivers or oceans.

DOT 5 cannot be used in trailer brake systems unless specifically stated by the actuator and brake manufacturer. DOT 5 does not absorb water, however the silicone in the DOT 5 makes the seals swell and can bind up caliper pistons.

Silicone has several other properties that make it less then desirable for trailer use. When forced thru small orifices under high pressure, like the solenoid valves in a disc brake system, it tends to foam, generating bubbles. Bubbles in brake fluid make for spongy brakes. Silicone also tends to become slightly compressible at temperatures near its boiling point, which makes it generally inappropriate for trailers used in mountain conditions. Tie Down Engineering brakes are designed for DOT3 or DOT 4 fluid ONLY. NEVER USE DOT 5.

Water can actually cause air to accumulate in your brake lines. Brake fluid is hygroscopic. It absorbs and retains water. The problem arises when the fluid has absorbed as much water as it possibly can and becomes saturated. Brake fluid is designed to have an extremely high boiling point; however, if you subject your tow vehicle and trailer to excessive braking, such as a trip through the mountains, you can easily cause the brake fluid to heat up to this temperature or beyond. When the brake fluid boils, especially when there is excessive water in the system, steam is a by-product. The braking system ultimately compresses this steam and turns it into water. The air separates from the water creating large pockets of air in your brake lines.

After only a year of service, the brake fluid in the average marine trailer may contain as much as two percent water. After 18 months, the level of contamination can be as high as three percent. And after several years of service, it is not unusual to find brake fluid that contains as much as seven to eight percent water.

As the concentration of moisture increases, it causes a sharp drop in the fluid’s boiling temperature. Brand new DOT 3 brake fluid must have a dry (no moisture) boiling point of at least 401 degrees F, and a wet (moisture-saturated) boiling point of no less than 284 degrees. Most new DOT 3 fluids exceed these requirements and have a dry boiling point that ranges from 460 degrees up to over 500 degrees.

Only one percent water in the fluid can lower the boiling point of a typical DOT 3 fluid to 369 degrees. Two percent water can push the boiling point down to around 320 degrees, and three percent will take it all the way down to 293 degrees, which is getting dangerously close to the minimum DOT and OEM requirements.

So consider this: After three years of service, the average boiling point of the brake fluid has dropped to a potentially dangerous level because of moisture contamination and may not meet minimum federal requirements for brake fluid.

Water Contamination increases the danger of brake failure because vapor pockets can form if the fluid gets too hot. Vapor displaces fluid and is compressible, so when the brakes are applied the actuator may completely compress without applying the brakes!

In addition to the safety issue, water-laden brake fluid promotes corrosion and pitting in caliper pistons and bores, wheel cylinders, master cylinders, steel brake lines and reverse solenoids.

From time to time we hear about reports of “unexplained” brake failures. When the vehicle’s brakes are inspected, no apparent mechanical fault can be found. The fluid level is normal, the linings are within specifications, the hydraulics appear to be working normally. Yet the brakes failed. Why? Because something made the brakes hot, which in turn overheated the fluid causing it to boil. The underlying cause often turns out to be dragging brakes caused by the E-stop cable being tripped, or the use of DOT 5 Fluid, but that is another story.

Posted Under:

Trailer Brakes

This post was written by

ghoj on July 18, 2011

Comments Off on Trailer Brake Fluid tips from Tie Down Engineering

Galvanized U-Bolts

If you have been towing a boat trailer for any length of time, then you probably have at least one roadside horror story to tell. Keeping a boat trailer safely on the road is not an easy task. Of course, salt water accelerates the corrosion process. Once a trailer is more that a couple of years old, it is wise to start inspecting the many trailer components at least once per year.

Most boat trailers are bolted together. You should always start by inspecting all bolts, nuts and washers, especially those that get immersed during launch and retrieve. The most important hardware to check is the u-bolts that fasten the leaf springs and axle together. These u-bolts actually are the only thing holding the axle to the rest of the trailer. A little surface rust is not a problem but corrosion will actually degrade the u-bolts to the point that they can no longer handle the stress imposed at this point. Other suspect hardware is as follows:

* Axle to spring tie plate u-bolts

* Leaf spring center pins

* Spring shackle bolts

* Spring hangers and equalizers

* Fender hardware

* Bunk/roller bracket to frame hardware

* Lug nuts/bolts, studs

* Cross-member to frame hardware

In addition, the frame, axles and cross-members should be inspected where it has contacted corroded hardware. We have seen a few incidents where the cross-member or axle integrity has been compromised at this point, especially on trailers with aluminum frames.

The solution to these corrosion problems is to replace the compromised hardware with new stainless or galvanized such as this:

1/2″ Galv. Square U-Bolt, 2-1/16″ x 4-13/16″ #86223

If you cannot find galvanized or stainless hardware, a good compromise is to use zinc-plated products with a good coat of a product such as this:

Instant Galvanize Spray Coating, 13 oz. #06054

There are already enough hazards on the road when towing a boat. Don’t wait for corrosion to reduce your safety footprint. Try some of these tips and tow your boat with a more secure feeling. You can find these products along with many replacement trailer parts at our online store TRAILER PARTS SUPERSTORE

Posted Under:

Uncategorized

This post was written by

ghoj on April 25, 2011

Comments Off on Do A Corrosion Check On Your Boat Trailer